Company Profile

ABOUT GUANFENG

GUANFENG is committed to development, design, manufacture, sales and installation on food processing equipment and overall food processing proposals.

20+ years of Industry-leading technology

GUANFENG is specialized in manufacturing VACUUM FREEZE DRYERS (FD), AUTOMATIC CONTINUOUS MULTISTAGE BELT DYRERS (AD),IQF FREEZER, as well as fruit and vegetable processing equipment. Based on experienced research and development engineers team and professional production team in the food processing industry, in addition to provide high quality equipment, we also provide the overall food processing solution.

View moreCorporate philosophy

Ushering in a new chapter of healthy food processing

View moreAmidst the surging wave of the wellness boom, we deeply understand the significance of healthy food ingredients. With exquisite craftsmanship and innovative technology, GUANFENG empowers global food enterprises, making the concept of wellness vividly embodied in every food product, providing a solid foundation for consumers' healthy dietary lives and collaborating with all sectors to build a bright future of healthy food.

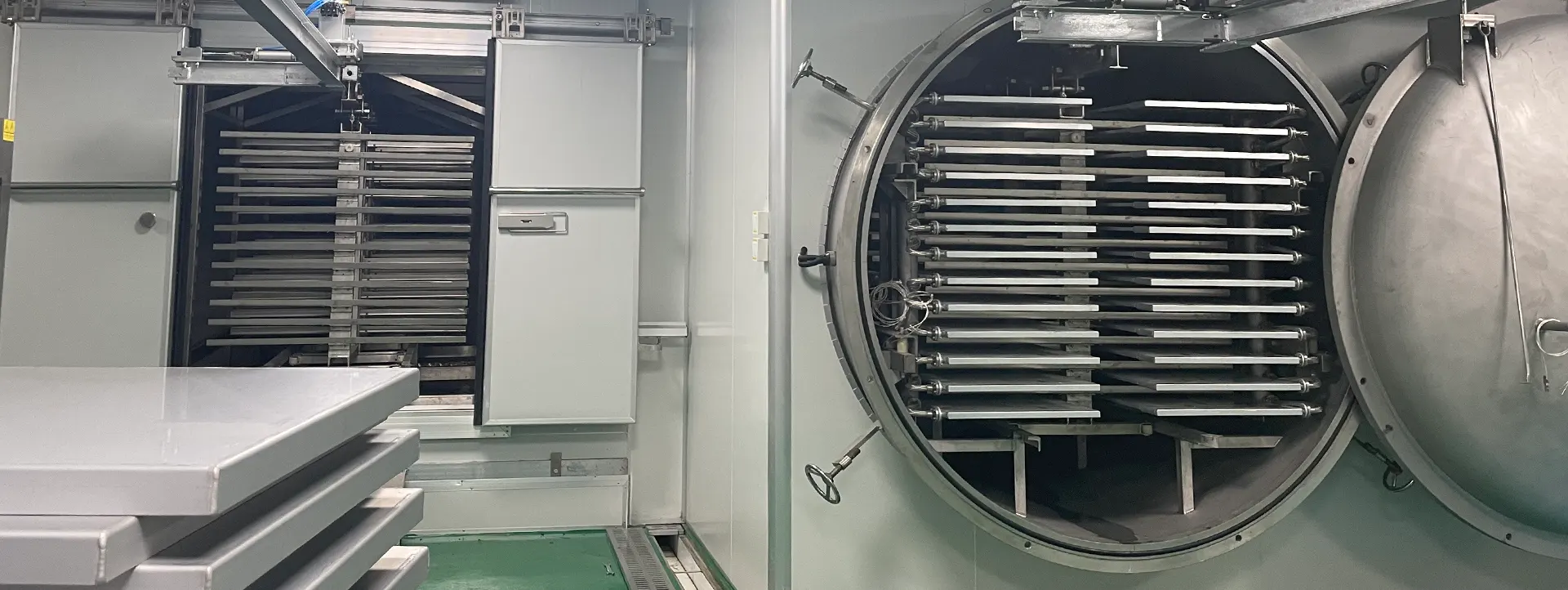

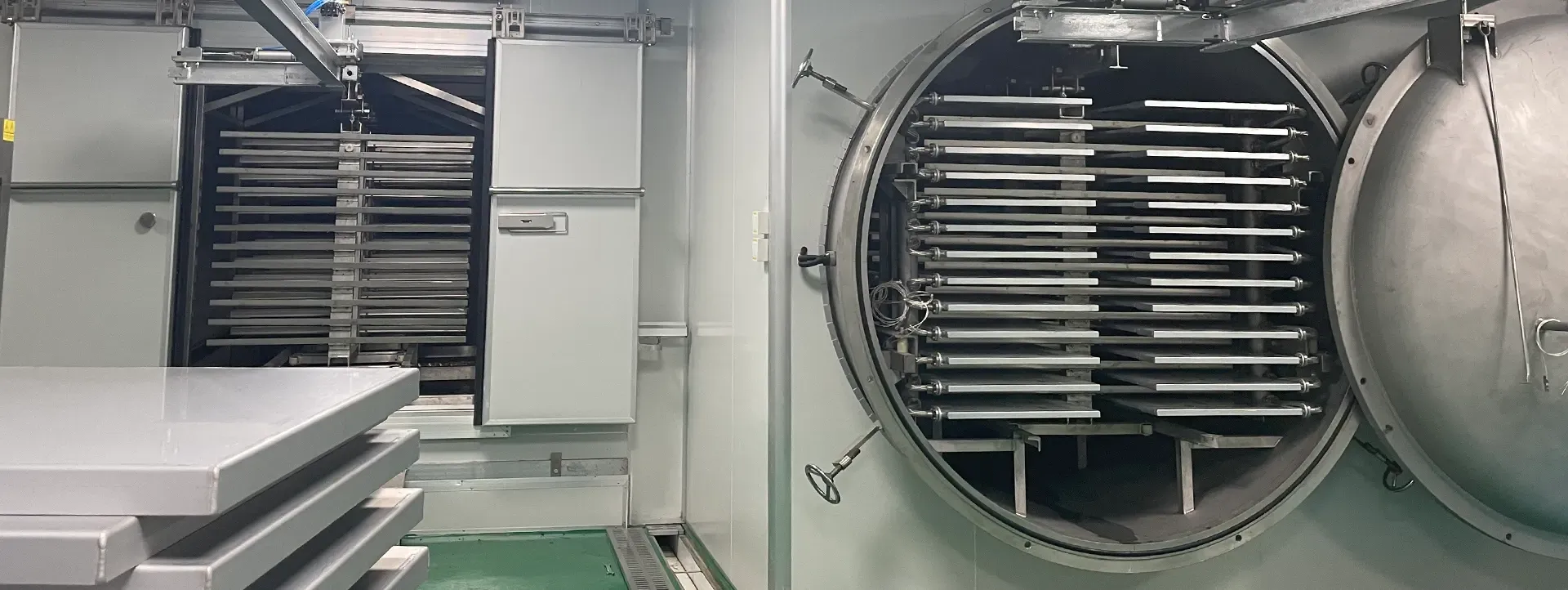

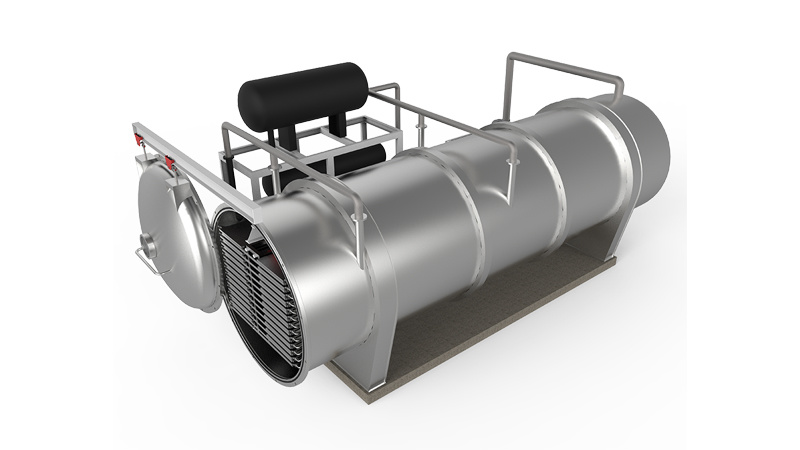

Processing time:10-20h</br> Vacuum time:<15 minutes</br> Refrigerant:R404A/R507</br> Cold trap working temperature:-30℃~-45℃</br> Control method:PLC</br> Heating method:Electric/Steam</br> Heating medium:Water,oil, silicone</br> Defrosting method:water defrosting/Automatic alternating defrosting </br>

Blueberry freeze dryer is a kind of equipment specially used for freeze-drying fresh blueberries, which converts the water in blueberries into gas through low temperature freezing and vacuum drying technology, thereby retaining the nutritional content, taste and color characteristics of blueberries, while extending the shelf life of the product, so It is widely used in the fruits processing industry to produce freeze-dried products, such as berry, melon, apricot, peach, mango etc..<br> GUANFENG specializes in crafting customized solutions, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

The Industrial Banana Freeze Dryer is dedicated to meeting the demands of large - scale industrial banana freeze - drying production. It features a highly efficient freeze - drying system, the precise temperature and vacuum control system can accurately regulate various parameters during the freeze - drying process.<br> GUANFENG specializes in crafting customized solutions for fruits freeze drying, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

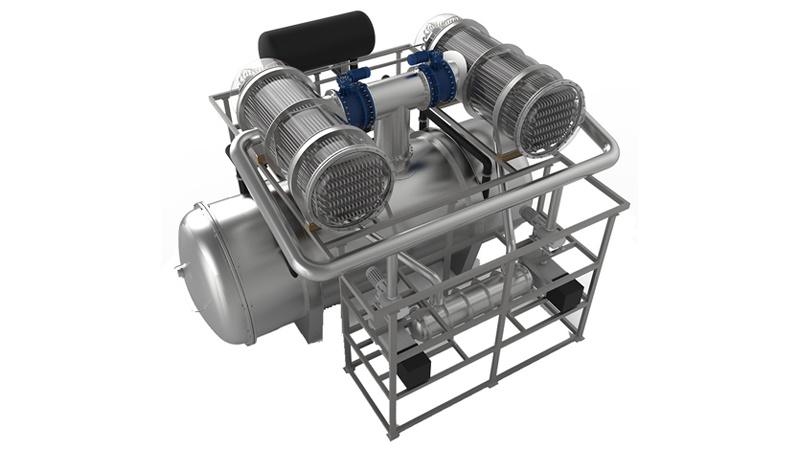

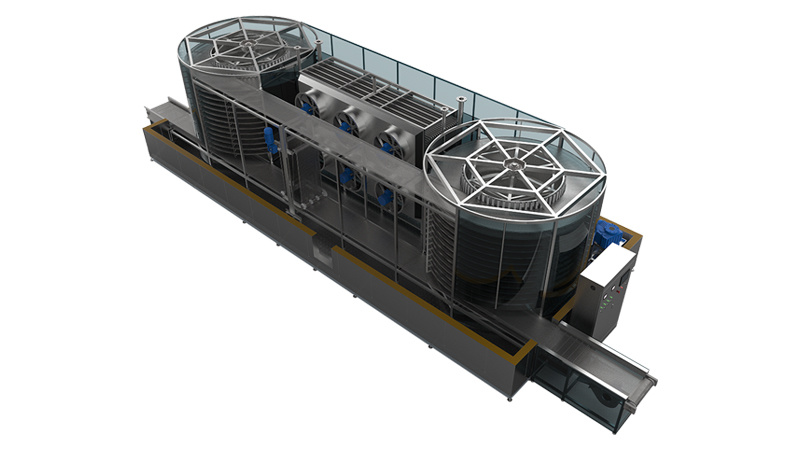

The spiral freezer produced by GUANFENG Food Machinery is applicable for prepared food, ice cream, pasta, meat and poultry, aquatic products, fried food, small packaged food, etc.<br> Double spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

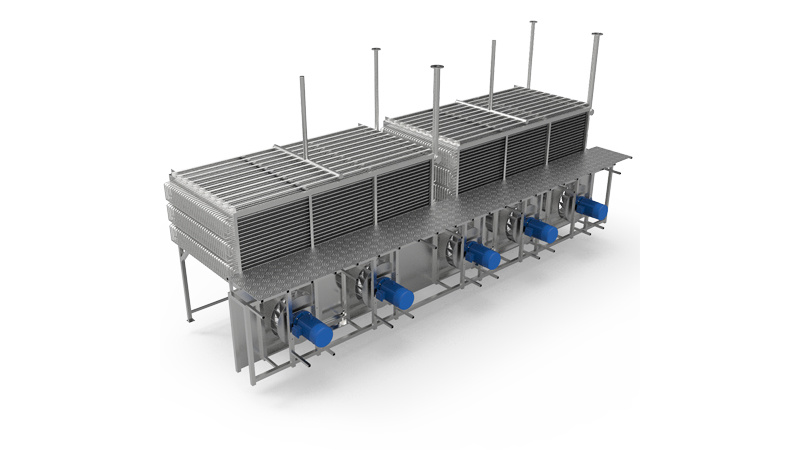

Tunnel quick-freezing machine is an efficient and versatile food quick-freezing equipment, which is unique in the use of stainless steel wire mesh belt or plastic steel mesh belt as a conveying system. This design allows the food to maintain a stable and uniform delivery during the freezing process, ensuring the consistency of the freezing effect.<br> The tunnel quick-freezing machine is especially suitable for a variety of prepared foods, such as steamed buns, dumplings, fish balls, etc., as well as aquatic products. Especially for those varieties that are not suitable for fluidized freezing, the tunnel IQF freezer provides a stable and uniform freezing environment, ensuring the quality and taste of the food.<br> In terms of freezing time, It offers a wide range of options ranging from 12 minutes to 100 minutes. This flexibility allows users to adjust the freezing time according to different food types and freezing needs to achieve the best freezing results.

The outstanding feature of Fluidized IQF freezer lies in the utilization of fluidization technology, which enables rapid and uniform freezing of food products. <br> Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors.<br> It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

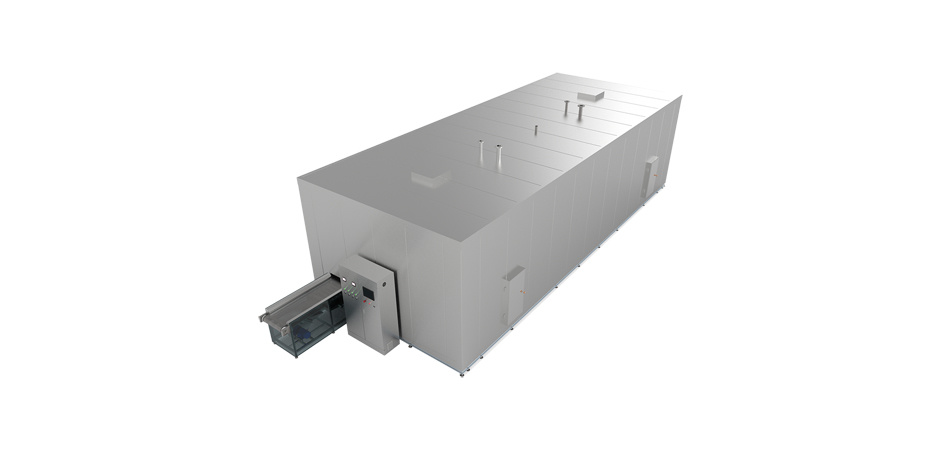

Belt dryer is a continuous flow drying equipment, especially suitable for drying sheet, strip and granular materials with good air permeability.<br> This innovative technology integrates automation and advanced drying principles to deliver consistent, high-quality results, enhancing the overall processing efficiency and product shelf life.

Belt dryer machine perform well in the mass production of low-drying, hard-to-dry materials. Its compact equipment structure and small footprint make the production line layout more flexible. At the same time, the characteristics of simple operation and convenient maintenance make the daily management and maintenance of the equipment more efficient. The stable operation of the belt dryer ensures a continuous and stable production process.<br> Belt dryer machine is a continuous flow drying equipment, especially suitable for drying sheet, strip and granular materials with good air permeability.<br> This innovative technology integrates automation and advanced drying principles to deliver consistent, high-quality results, enhancing the overall processing efficiency and product shelf life.

A Spiral Freezer Machine is an innovative freezing solution designed for high-capacity food processing. It uses a spiral conveyor system to transport products through a controlled freezing environment, ensuring rapid and uniform freezing. Ideal for products like meat, seafood, poultry, and ready-to-eat meals, this machine maximizes space efficiency and maintains product quality. Its continuous operation and compact design make it a top choice for industries requiring large-scale, efficient freezing.

Heat Pump Fruit Drying Machine

Heat pump fruit drying machine manufactured by GUANFENBG Food Machinery is suitable for a wide range of products, including large preserved fruits, herbs, aquatic products, meat products, and other items that require extended processing times or demand high product quality. Specifically, it is suitable for drying mangoes, red dates, medlars, sweet potato strips, momordicas grosvenoris, figs, mushrooms, fish, sausages, ginseng, Chinese yams, clay materials, pasty fluids, and sludge.<br> Heat pump fruit drying machine consists of finned evaporator, compressor, condenser and expansion valve, which transfers external heat to the inside of the dryer through a continuous heat cycle of evaporation, compression and condensation.

Food Processing Solutions

CASE

PROJECT

Project progress

Empower global food enterprises, equip with top-notch facilities and services.

View moreGUANFENG has firmly established its presence across over 40 countries worldwide. Our footprint, which encompasses diverse regions from North America to Asia and Europe, is not only a physical manifestation of our global reach but also a symbol of our unwavering commitment to innovation and quality in the food processing industry.

Uzbekistan Vacuum freeze dryer machine project (一)

Project location:

Project location: Peru

Project location: Uzbekistan

Vegetable IQF Freezing Project

Project location: India

Project location: India

Project location: Uzbekistan

BLOG

2025-10-24

2025-10-24

Zhejiang Guanfeng Food Machinery Co., Ltd. has customized a 1.5TIQF fluidized freezing production line for Kazakhstan customers, which has been video inspected on October 13th. On October 13, 2025, Zhejiang Guanfeng Food Machinery Co., Ltd. announced that the 1.5TIQF fluidized freezing equipment, including pre-treatment equipment, tailored for customers in Kazakhstan has been successfully produced. The Kazakhstan customer has conducted video inspection and scheduled shipment. This equipment is used for producing high protein powder, mainly made from fruit fly larvae, to assist customers in achieving independent mass production of high protein powder and leading the industry.

2025-07-21

2025-07-21

Choosing the appropriate spiral freezer for food processing

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.