2025-07-21

Choosing the appropriate spiral freezer for food processing

In the food processing industry, rapid and effective freezing is crucial for maintaining the quality and safety of perishable products. An important factor when choosing a suitable spiral freezer to freeze seafood, fish, poultry, and meat products is the capacity of the spiral freezer. Different products and volumes may require different capacities to ensure effective and timely freezing. The self stacking spiral freezer is suitable for large-scale processing, while the quick freezing double spiral freezer provides the flexibility to handle multiple product lines simultaneously.

2025-07-18

How can a freeze dryer "change the fate" of food and life?

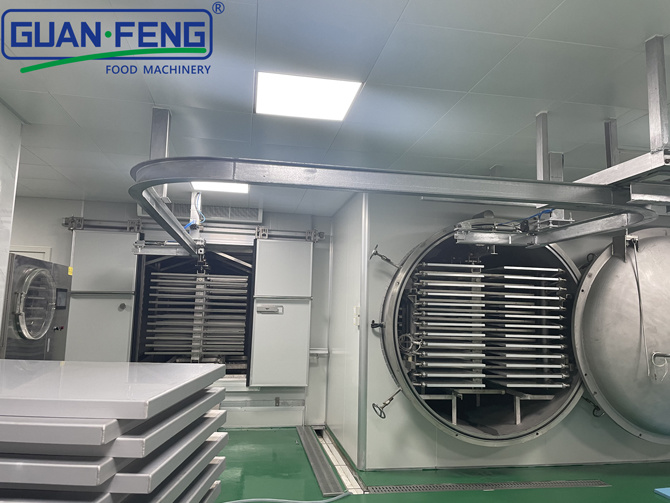

The freeze-drying machine seals fresh life and perishable food outside of time and space for a long time, creating an instant revival and delicious taste on the tongue, silently changing food, medicine, and even the future. 1、 The core of freeze-drying is gentle freezing and vacuum The freeze-drying technology of freeze-drying machine is different from the simple and rough traditional high-temperature drying. The charm of freeze-drying lies in its gentle and precise three steps: 1. Pre freezing: Press the "pause button" for the material Place materials (liquids, solids, or slurries) containing moisture in extremely cold environments at -40 ° C or even lower, and quickly freeze the internal moisture into solid ice crystals. This is like pressing a precise pause button on biological molecules - the structure is fixed and the activity is well preserved.

2025-07-11

Principle of vacuum freeze-drying

1. Definition and advantages of vacuum freeze-drying The product is completely frozen and the ice crystals are sublimated under certain vacuum conditions, thus achieving the purpose of low-temperature dehydration. This process is called freeze-drying The freeze-dried solid material exhibits a porous structure due to the sublimation of tiny ice crystals and maintains its original frozen volume. Upon addition of water, it easily dissolves and reverts to its original state.

2025-07-10

Operation steps and lyophilization process of vacuum freeze dryer

Vacuum freeze dryer is a kind of drying equipment that uses the moisture in the material to be removed in the form of condensate. After lyophilization, the material can retain the active ingredient while reducing the volume and weight, extending the storage cycle, and making it easy to store and transport. There are many people who do not know much about this equipment, so I will talk about its operation steps and briefly introduce the freeze-drying process.

2025-07-09

How to reduce the production cost of freeze-drying machine

There are three factors that affect the operating cost of freeze-drying machines: 1. The influence of materials, such as eutectic point, thermal sensitivity, geometric size or thickness, can have a significant impact on the required drying time and operating costs; 2. The impact of the adopted process route, such as the final freezing temperature, freezing rate, heating temperature, heating rate, and determination and control of the machine, will affect the drying speed and operating costs of the materials. 3. The impact of the freeze dryer itself. The performance, limit parameter indicators, comprehensive capacity, energy utilization rate, operational stability, and ease of operation of freeze-drying machines can all have an impact on drying efficiency and operating costs, and even have a serious impact.

2025-07-08

Application of Vacuum Freeze Drying Technology in Drying and Processing of Chinese Herbal Medicine

One important factor to consider in the processing of traditional Chinese medicine is long-term preservation without losing its medicinal properties. In the past, the purpose of drying was mainly to remove moisture or solvents from certain raw materials, semi-finished products, and finished products, reducing the weight and volume of drugs, food, and other materials for easy processing, use, transportation, and storage.

2025-07-07

Application of Intelligent Control Technology in Food Vacuum Freeze Drying Machine

Food vacuum freeze-drying technology, as an efficient and energy-saving food processing method, is gradually becoming an important direction for the upgrading of the food industry. Application of Intelligent Control Technology in Food Vacuum Freeze Drying Machine 1、 Key advantages of vacuum freeze-drying technology for food Vacuum freeze-drying technology removes moisture from materials through low-temperature sublimation, preserving the color, aroma, taste, and nutritional components of food to the greatest extent possible, while significantly extending the shelf life. Its core advantages include:

2025-07-04

Pet food freeze dryer preserves food through low-temperature freezing and vacuum dehydration. FD freeze drying can retain more than 95% of the nutrients in the ingredients, maintaining their original shape, color, and flavor. Traditional high-temperature drying or air drying can cause the materials to shrink and dry. Pet food freeze dryer (pet freeze dryer) uses low-temperature freezing and vacuum drying technology to directly remove the moisture in pet food (cat food, dog food, pet snacks, etc.) from solid ice to gaseous state, ultimately obtaining freeze-dried pet food with a moisture content of<5%.

2025-07-02

The reasons for the leakage rate of the vacuum freeze dryer.

There are two indicators that can measure the sealing performance of a container in a vacuum freeze dryer: "rise rate" and "leakage rate". The pressure rise rate refers to the pressure change of a "vacuum" container over a certain period of time. The unit is usually mbar/s or mTorr/min. The calculation formula is as follows:

2025-06-30

Application of Sichuan pepper freeze-drying and freeze-drying machine in seasoning

Sichuan pepper is a unique seasoning, loved by countless food enthusiasts for its spiciness and numbing sensation. Sichuan pepper, as a common spice and medicinal herb, has a certain spicy taste and aroma, and is commonly used in various dishes in Chinese cuisine. Traditional drying methods may weaken the aroma and numbing taste of Sichuan pepper, while freeze-drying technology can maximize the preservation of the original flavor and nutritional components of Sichuan pepper.

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.