GUANFENG FOOD MACHINERY

main products include freeze-drying, drying, quick freezing, deep frying, pre-treatment, liquid nitrogen freezing, sterilization, cold chain storage and other food machinery equipment

Products Category

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

Spiral Freezer Machine

Product Category:

|

Spiral Freezer Machine Configuration |

|

|

Structure |

Double; Single |

|

Drum diameter |

1650-3900mm |

|

Layers |

7-25 |

|

Mesh belt width |

520-1050mm |

|

Infeed/Outfeed length |

2000mm/1000mm |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Control panel |

PLC |

|

Defrosting method |

Water/hot gas/ADF |

|

Spiral Freezer Machine Configuration |

|

|

Structure |

Double; Single |

|

Drum diameter |

1650-3900mm |

|

Layers |

7-25 |

|

Mesh belt width |

520-1050mm |

|

Infeed/Outfeed length |

2000mm/1000mm |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Control panel |

PLC |

|

Defrosting method |

Water/hot gas/ADF |

- Product Detail

- Product advantages

- 产品概要表格

-

- Commodity name: Spiral Freezer Machine

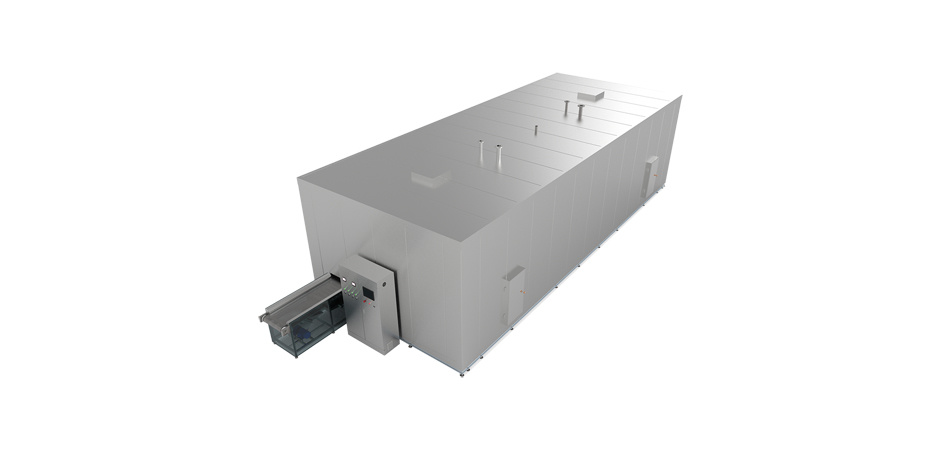

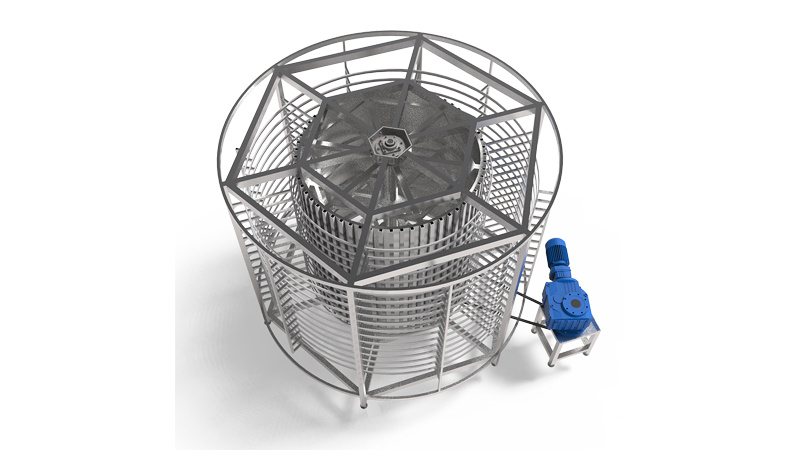

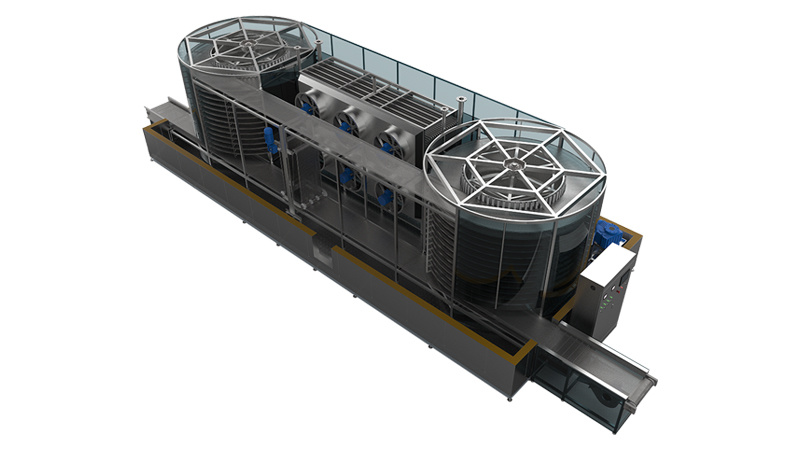

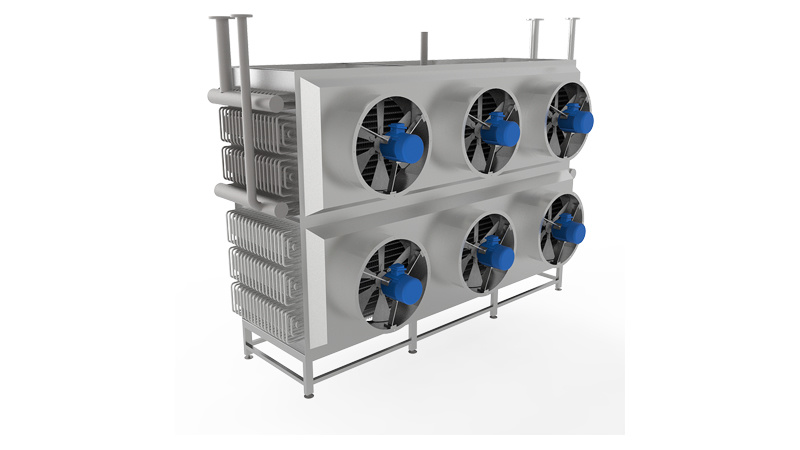

A Spiral Freezer Machine is an innovative freezing solution designed for high-capacity food processing. It uses a spiral conveyor system to transport products through a controlled freezing environment, ensuring rapid and uniform freezing. Ideal for products like meat, seafood, poultry, and ready-to-eat meals, this machine maximizes space efficiency and maintains product quality. Its continuous operation and compact design make it a top choice for industries requiring large-scale, efficient freezing.

-

-

Spiral Freezer Machine Configuration

Structure

Double; Single

Drum diameter

1650-3900mm

Layers

7-25

Mesh belt width

520-1050mm

Infeed/Outfeed length

2000mm/1000mm

Refrigerant

Freon, Ammonia, CO2

Control panel

PLC

Defrosting method

Water/hot gas/ADF

Hot Tags:

GUANFENG FOOD MACHINERY

Product

Applications

Bakery Products

The spiral freezer can freeze the raw bread dough, pizza dough, croissant, baked bread, buns. It can quickly lock the water and nutrition of food, maintain its original taste and flavor.

Seafood Products

By gently removing water through freeze - drying, our equipment helps retain the delicate flavor and texture of seafood, making it a great option for seafood processing.

Meat Products

To remove moisture from meat products, extending their shelf life while maintaining the texture and taste, suitable for a wide range of meat types

Poultry Products(cooked)

Our spiral freezers are also popular and efficient in freezing the fried chicken nuggets for major fast food chains.

Ready Meals

The freeze dryers are capable of preserving complete ready meals, ensuring that the flavors and ingredients remain intact, ready for quick reconstitution

Ice Cream

Ice cream needs to be frozen quickly to maintain taste and quality, and spiral freezer can provide a stable low temperature environment to ensure that ice cream is frozen quickly and evenly.

GUANFENG FOOD MACHINERY

Product

Recommendation

It is suitable for prepared food, ice cream, pasta, meat and poultry, aquatic products, fried food, small packaged food, and other vegetables which are unfavorable by IQF, which has became the most popular one in the food company.

Double spiral frozen machine positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

It is suitable for prepared food, ice cream, pasta, meat and poultry, aquatic products, fried food, small packaged food, and other vegetables which are unfavorable by IQF, which has became the most popular one in the food company.

Double spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

It is suitable for prepared food, ice cream, pasta, meat and poultry, aquatic products, fried food, small packaged food, and other vegetables which are unfavorable by IQF, which has became the most popular one in the food company.

Double cryogenic spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

Double spiral freezing machine positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

Double spiral belt freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed. With its unique spiral design and efficient freezing technology, spiral belt freezer has quickly become the new favorite of food enterprises.

Double IQF spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

Double Frozen spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

Double spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers. Single spiral with different level of infeed and outfeed.

Get

A Quote

Please leave your email address, our professionals will contact you as soon as possible!

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.