GUANFENG FOOD MACHINERY

main products include freeze-drying, drying, quick freezing, deep frying, pre-treatment, liquid nitrogen freezing, sterilization, cold chain storage and other food machinery equipment

Products Category

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

IQF Blast Freezer

Product Category:

|

IQF Blast Freezer Configuration |

|

|

Freezing time |

8~40min |

|

Inlet temperature |

+15℃ |

|

Outlet temperature |

-18℃ |

|

freezer temperature |

<-35℃ |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Defrosting method |

Water/Air/Hot gas defrosting |

|

Control panel |

PLC |

|

Heat preservation library |

Double-sided stainless steel polyurethane insulation |

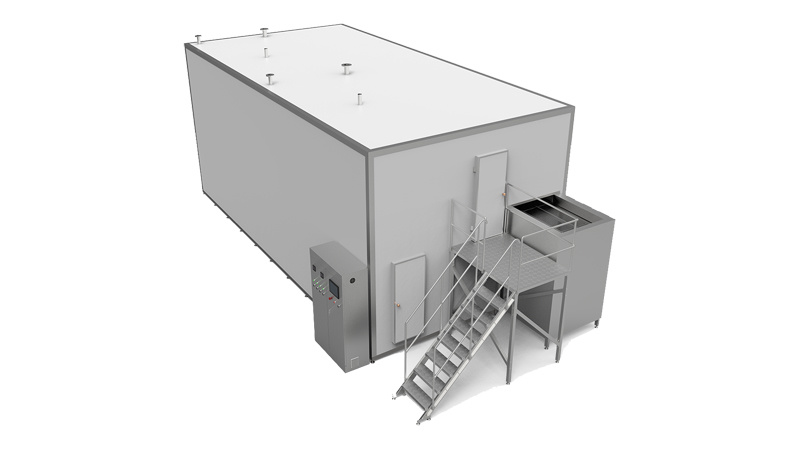

The IQF Blast Freezer offers users a superior freezing experience by leveraging powerful blast freezing technology. This advanced iqf machine rapidly brings the freezer temperature below -35°C, freezing products from +15°C to -18°C in a remarkably short time frame of 8 to 40 minutes. This rapid process is the key to achieving true Individual Quick Freezing, where each piece of product is frozen separately. This prevents the formation of large ice crystals and clumps, thereby perfectly preserving the cellular structure of the food. For operators, this means the final product retains its original texture, juiciness, and appearance after thawing, significantly enhancing its market value. The automated PLC control panel simplifies operation, allowing for consistent and repeatable results with minimal manual intervention.

Constructed with a robust double-sided stainless steel polyurethane insulation cabinet, this quality iqf machine is built for durability and energy efficiency. It maintains a stable freezing environment while minimizing thermal loss. The flexibility in refrigerant options, including Freon, Ammonia, and CO2, allows this IQF freezer machine to adapt to various operational needs and environmental regulations. Furthermore, multiple defrosting method choices such as water, air, or hot gas defrosting provide operational flexibility to suit different production schedules and maintenance preferences. This combination of speed, precision, and adaptability makes this iqf machine an indispensable asset for processors seeking to deliver premium frozen products.

The IQF Blast Freezer offers users a superior freezing experience by leveraging powerful blast freezing technology. This advanced iqf machine rapidly brings the freezer temperature below -35°C, freezing products from +15°C to -18°C in a remarkably short time frame of 8 to 40 minutes. This rapid process is the key to achieving true Individual Quick Freezing, where each piece of product is frozen separately. This prevents the formation of large ice crystals and clumps, thereby perfectly preserving the cellular structure of the food. For operators, this means the final product retains its original texture, juiciness, and appearance after thawing, significantly enhancing its market value. The automated PLC control panel simplifies operation, allowing for consistent and repeatable results with minimal manual intervention.

Constructed with a robust double-sided stainless steel polyurethane insulation cabinet, this quality iqf machine is built for durability and energy efficiency. It maintains a stable freezing environment while minimizing thermal loss. The flexibility in refrigerant options, including Freon, Ammonia, and CO2, allows this IQF freezer machine to adapt to various operational needs and environmental regulations. Furthermore, multiple defrosting method choices such as water, air, or hot gas defrosting provide operational flexibility to suit different production schedules and maintenance preferences. This combination of speed, precision, and adaptability makes this iqf machine an indispensable asset for processors seeking to deliver premium frozen products.

|

IQF Blast Freezer Configuration |

|

|

Freezing time |

8~40min |

|

Inlet temperature |

+15℃ |

|

Outlet temperature |

-18℃ |

|

freezer temperature |

<-35℃ |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Defrosting method |

Water/Air/Hot gas defrosting |

|

Control panel |

PLC |

|

Heat preservation library |

Double-sided stainless steel polyurethane insulation |

- Product Detail

- Product advantages

- 产品概要表格

-

- Commodity name: IQF Blast Freezer

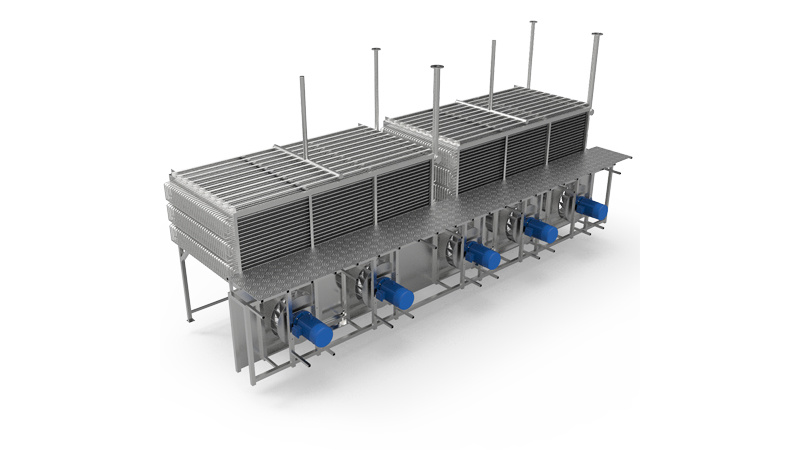

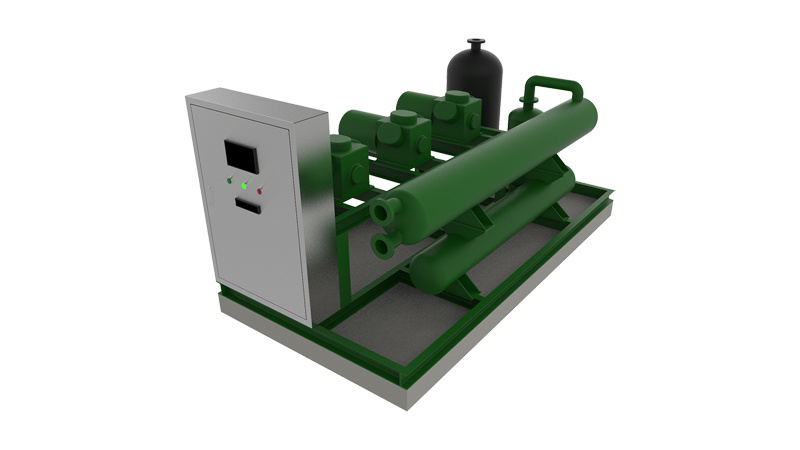

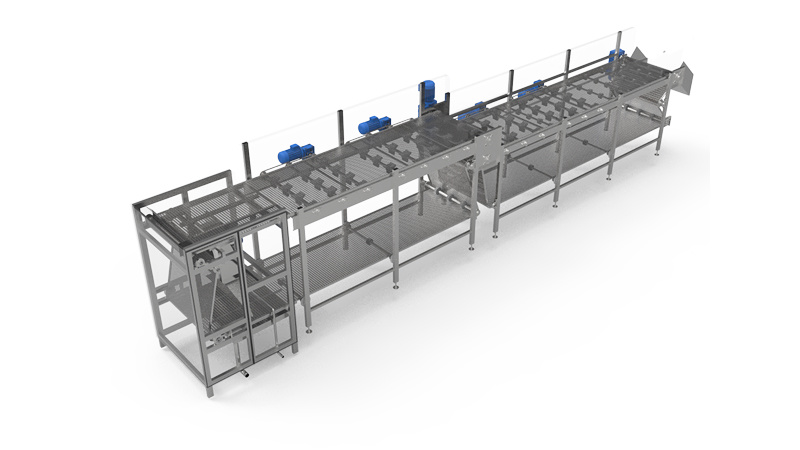

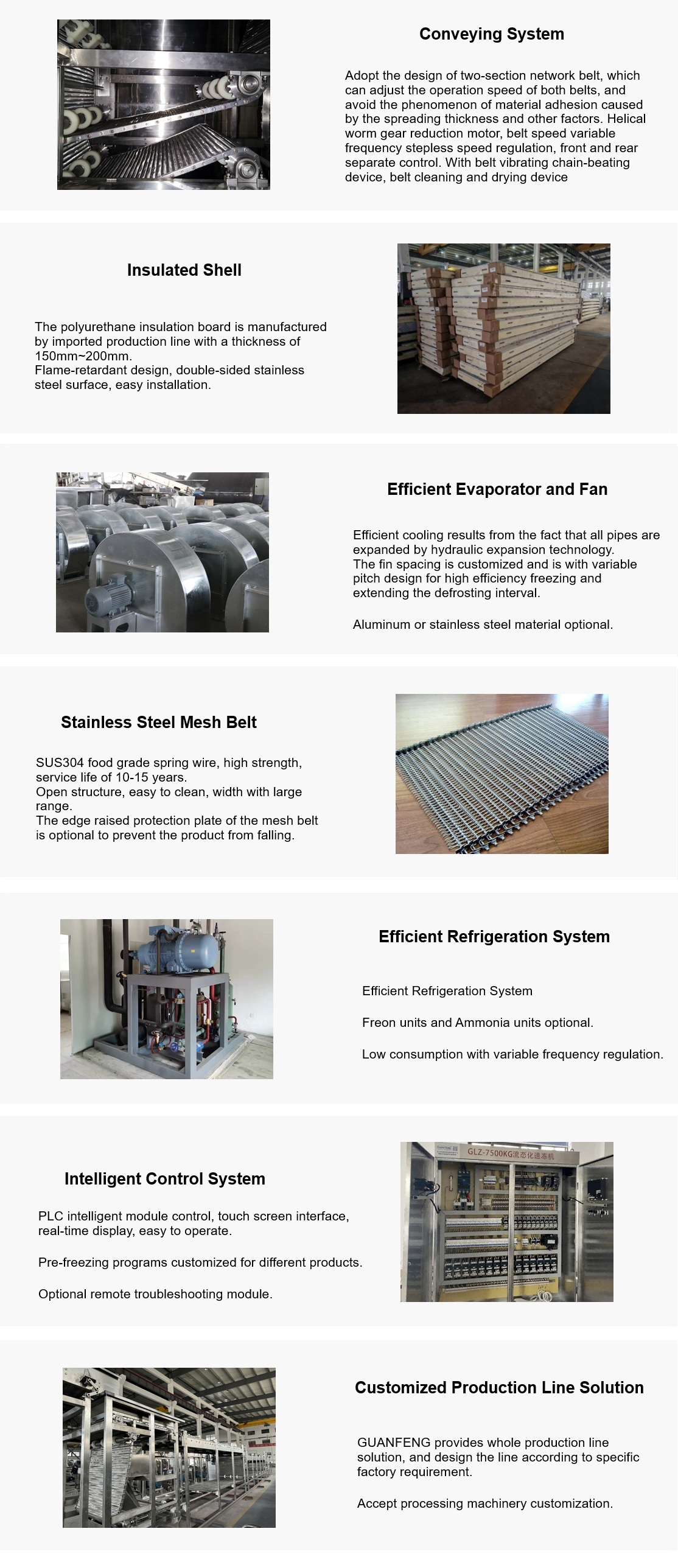

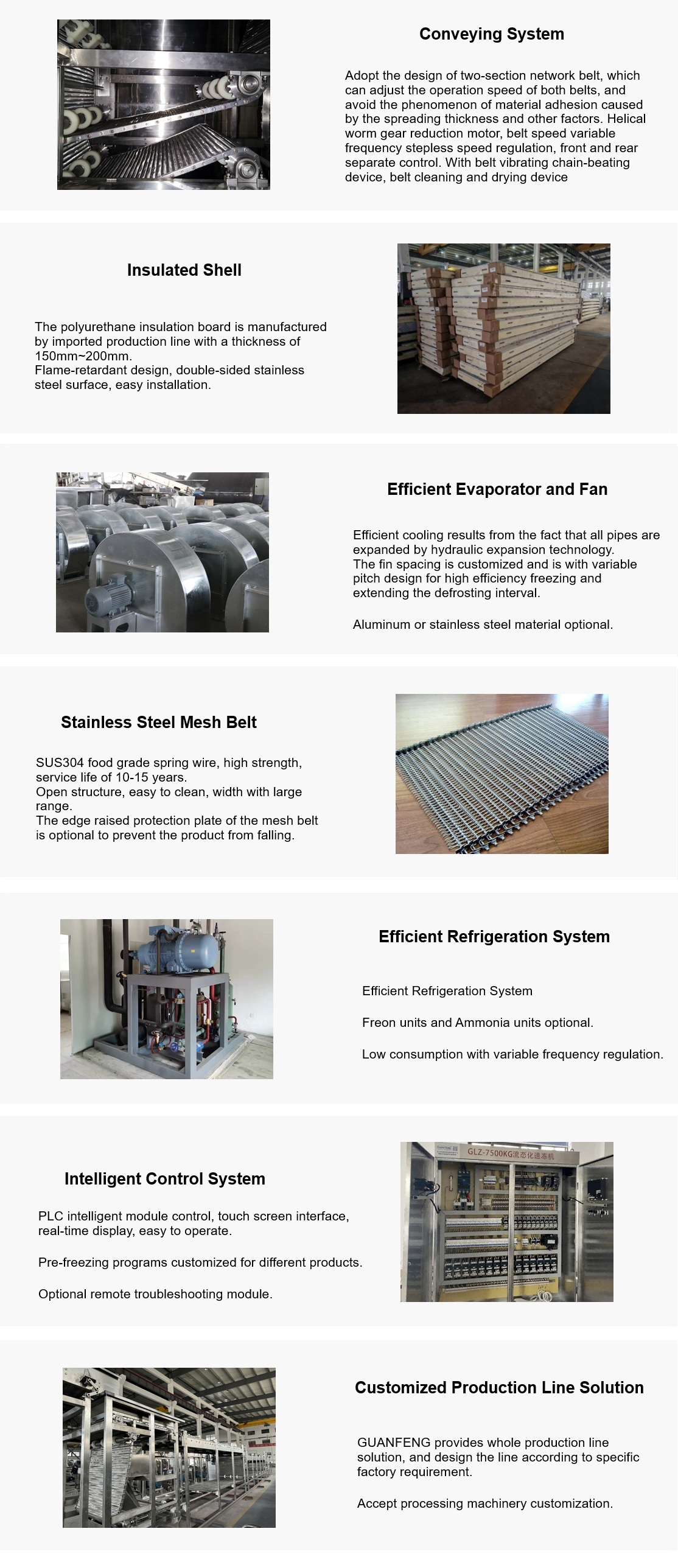

The IQF blast freezer, standing for Individual Quick Freezing, is a highly efficient food freezing equipment widely utilized in the food processing industry. This technology preserves the quality and nutritional content of food products by rapidly freezing them individually.The IQF blast freezer involves the rapid freezing of food items on an individual basis. The process exposes foods to extremely low temperatures in a short period, preventing the formation of large ice crystals on the surface and within the food. By rapidly lowering the temperature, IQF technology maintains the food's original shape, texture, and taste.It adopts a number of new technologies and processes to improve the quality of frozen products, prevent the leakage of mesh belt, reduce the breakage rate, and achieve uniform wind around the frozen products at the same time.The machine is made of stainless steel and designed according to HACCP requirements, in line with international food (safety) hygiene standards. It is widely used to process: green beans, edamame (edamame kernel), peas, snow pea, mushrooms, white cauliflower, green cauliflower, diced carrots, corn kernels and other vegetables and fruits.Technical parameters Model / ParametersGLZ-0.5GLZ-1.0GLZ-1.5GLZ-2.0GLZ-3.0Capacity(kg/h)5001000150020003000Overall dimensions(m)7.0*3.8*4.058.0*4.5*4.0510.0*4.5*4.0511.04*4.5*4.0514.5*4.5*4.05Length of freezing room(m)5.06.08.09.012.5Inlet material temperature(℃)+15Outlet material temperature(℃)-18Freezing temperature(℃)≤-33Freezing time(min)4-40(variable frequency regulation)RefrigerantR22/R404A/R717Cold Consumption(kw)95165245325490Installation Power(kw)30.946.361.474.2101.7 Features The IQF blast freezer is equipped with the two-section type net belt conveying which could satisfy the processing different raw materials. Conveyor and fan speed can be adjusted independently.The initial freezing section is provided with air bypass pulse device to enhance the fluidized effect so as to realize the rapid freezing.The ADS air automatic defrosting device can be adopted to maintain the frost thickness of the evaporator always under 3mm and ensure that the quick-freezing machine can carry out 24-hour continuous production. The heat exchanging efficiency of the evaporator is greatly enhanced, and the power consumption of refrigerating compressor and fan is reduced. For quick- freezing output per unit, about 20% of power consumption can be saved.All parts are made of stainless steel, aluminum alloy and food level plastics, which complies with the food hygienic standards.The high-efficiency cleaning device is provided to clean the residues on the net belt; all designs guarantee the facility and easy operation for cleaning and ensure hygienic safety of foods. Important parts display Conveying system ☆Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors.☆Belt drive motor: helical worm gear reduction motor, belt speed variable frequency stepless speed regulation, front and rear separate control.☆The mesh belt adopts wear resistant roller and bracket to reduce the wear and running resistance of the mesh belt, extending the service life of the mesh belt.☆Add abrasion-resistant rubber strip on both sides of the mesh belt, prevent leakage in the warehouse.☆Equipped with belt vibrating chain-beating device and belt cleaning and drying device.> Evaporator and Fan ☆Large aluminum alloy aluminum tube fin, the advanced technology of mechanical hydraulic pipe makes the aluminium tightly wrapped in aluminium tube, with efficient refrigeration, not easy to frost, extend frosting time, frost quickly and thoroughly, convenient to clean, minimize health dead Angle of bacterial growth.☆Multi-in and out welding is adopted for pipe elbow of evaporator to improve refrigeration efficiency.☆In view of the characteristics of high humidity, high temperature and rapid frost gathering at the feed end, the structure of the evaporator is different, and the sheet spacing of each evaporator is designed with variable sheet spacing to ensure continuous and efficient freezing of the quick-freezing function and extend the frost interval.>Refrigeration System ☆The refrigeration system is the core part of the IQF blast freezer, which removes heat from the object or space being cooled through a series of physical and chemical processes to achieve the cooling effect.☆Compressors can be customized, normally adopt Bitzer from Germany, Hanbell from Taiwan China, Refcomp from Italy.☆Refrigeration system is optional: Freon refrigeration, ammonia refrigeration, carbon dioxide refrigeration.> Electric cabinet ☆Vertical cabinet structure, the shell is made of stainless steel.☆Electrical components: the electrical components are Schneider or CHNT. PLC and touch screen are Siemens.☆Temperature display: multi-point display (inlet, outle

IQF Blast Freezer Introduction:

Fluidized IQF freezer freezes materials quickly and evenly through fluidization technology. It adopts a two-section mesh belt design, which can adjust the running speed of the two sections of mesh belts to avoid the phenomenon of material adhesion caused by factors such as the thickness of the fabric. It is suitable for various foods, including but not limited to fresh vegetables, fruits, frozen dumplings, shrimp and various small foods.

IQF Blast Freezer Video:

IQF Blast Freezer Parameter:

Model

GLZ-1.0

GLZ-1.5

GLZ-2.0

GLZ-3.0

GLZ-3.0

Capacity(kg/h)

500

1000

1500

2000

3000

Overall dimensions(m)

7.0*3.8*4.05

8.0*4.5*4.05

10.0*4.5*4.05

11.04*4.5*4.05

14.5*4.5*4.05

Length of freezing room(m)

5.0

6.0

8.0

9.0

12.5

Inlet material temperature(℃)

+15

Outlet material temperature(℃)

-18

Freezing temperature(℃)

≤-33

Freezing time(min)

4-40(variable frequency regulation)

Refrigerant

R22/R404A/R717

Cold Consumption(kw)

95

165

245

325

490

Installation Power(kw)

30.9

46.3

61.4

74.2

101.7

-

The IQF Blast Freezer offers users a superior freezing experience by leveraging powerful blast freezing technology. This advanced iqf machine rapidly brings the freezer temperature below -35°C, freezing products from +15°C to -18°C in a remarkably short time frame of 8 to 40 minutes. This rapid process is the key to achieving true Individual Quick Freezing, where each piece of product is frozen separately. This prevents the formation of large ice crystals and clumps, thereby perfectly preserving the cellular structure of the food. For operators, this means the final product retains its original texture, juiciness, and appearance after thawing, significantly enhancing its market value. The automated PLC control panel simplifies operation, allowing for consistent and repeatable results with minimal manual intervention.

Constructed with a robust double-sided stainless steel polyurethane insulation cabinet, this quality iqf machine is built for durability and energy efficiency. It maintains a stable freezing environment while minimizing thermal loss. The flexibility in refrigerant options, including Freon, Ammonia, and CO2, allows this IQF freezer machine to adapt to various operational needs and environmental regulations. Furthermore, multiple defrosting method choices such as water, air, or hot gas defrosting provide operational flexibility to suit different production schedules and maintenance preferences. This combination of speed, precision, and adaptability makes this iqf machine an indispensable asset for processors seeking to deliver premium frozen products.

-

IQF Blast Freezer Configuration

Freezing time

8~40min

Inlet temperature

+15℃

Outlet temperature

-18℃

freezer temperature

<-35℃

Refrigerant

Freon, Ammonia, CO2

Defrosting method

Water/Air/Hot gas defrosting

Control panel

PLC

Heat preservation library

Double-sided stainless steel polyurethane insulation

GUANFENG FOOD MACHINERY

Product

Applications

Variety Fruits & Vegetables

GUANFENG freeze dryers can preserve the natural color, flavor, and nutritional value of various fruits and vegetables, making them convenient for long - term storage and rehydration.

Meat Products

To remove moisture from meat products, extending their shelf life while maintaining the texture and taste, suitable for a wide range of meat types

Ready-to-Eat Products

Frozen foods such as French fries, tangyuan (glutinous rice balls), and steamed buns are also processed using fluidized bed quick freezers. This technology ensures that ready-to-eat products maintain their taste and nutrition during freezing, convenient for consumers to enjoy at any time.

GUANFENG FOOD MACHINERY

Product

Recommendation

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Individual IQF Quick Freezing Machine

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

French Fries IQF Freezing Line

IQF is a food freezing technology that has attracted much attention in recent years. The technology uses a special freezing method to freeze french fries in a short period of time at ultra-low temperatures. Because the french fries are subdivided and treated individually during the quick-freezing process, the freezing efficiency is extremely high, which can quickly lock in the flavor and nutrition of the fries.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Individual Quick Freezing Machine

Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors. The first stage is quick freezing the surface temperature of the chips to the freezing temperature. The chips don’t stick and showing a perfect fluidization effect under the action of the mechanical vibration device. The second stage of deep freezing to ensure the freezing effect of the product.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Adopt the design of two-section network belt, which can adjust the operation speed of both belts, and avoid the phenomenon of material adhesion caused by the spreading thickness and other factors.

It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

Get

A Quote

Please leave your email address, our professionals will contact you as soon as possible!

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.