GUANFENG FOOD MACHINERY

main products include freeze-drying, drying, quick freezing, deep frying, pre-treatment, liquid nitrogen freezing, sterilization, cold chain storage and other food machinery equipment

Products Category

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

IQF Quick Frozen Machine

Product Category:

|

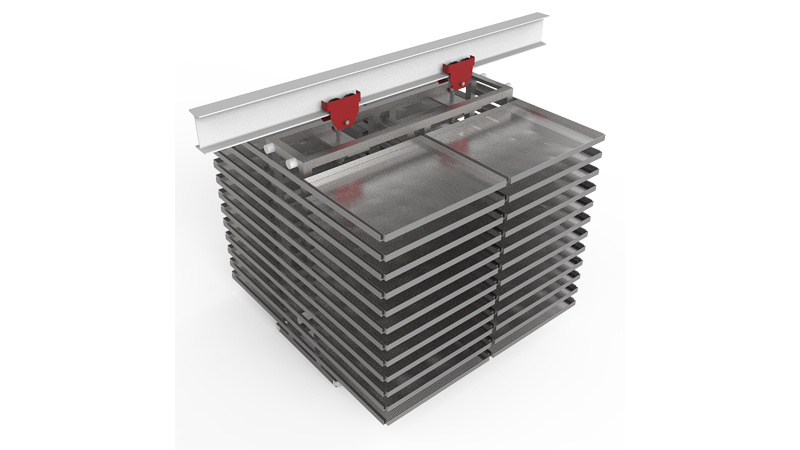

IQF Quick Frozen Machine Configuration |

|

|

Freezing time |

8~40min |

|

Inlet temperature |

+15℃ |

|

Outlet temperature |

-18℃ |

|

freezer temperature |

<-35℃ |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Defrosting method |

Water/Air/Hot gas defrosting |

|

Control panel |

PLC |

|

Heat preservation library |

Double-sided stainless steel polyurethane insulation |

|

IQF Quick Frozen Machine Configuration |

|

|

Freezing time |

8~40min |

|

Inlet temperature |

+15℃ |

|

Outlet temperature |

-18℃ |

|

freezer temperature |

<-35℃ |

|

Refrigerant |

Freon, Ammonia, CO2 |

|

Defrosting method |

Water/Air/Hot gas defrosting |

|

Control panel |

PLC |

|

Heat preservation library |

Double-sided stainless steel polyurethane insulation |

- Product Detail

- Product advantages

- 产品概要表格

-

- Commodity name: IQF Quick Frozen Machine

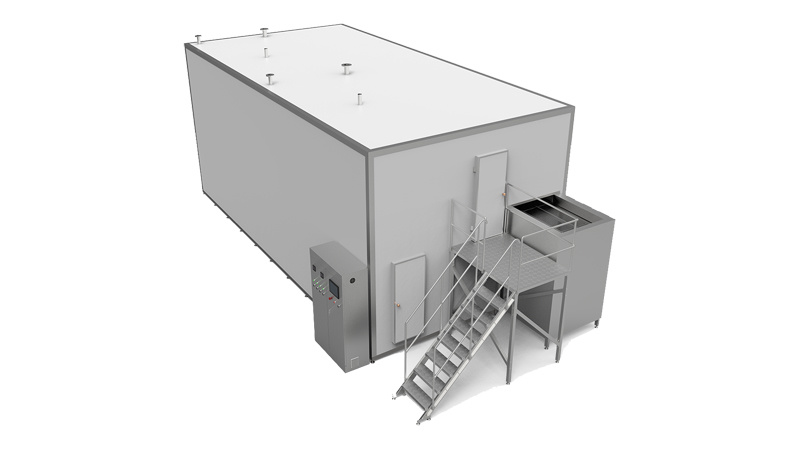

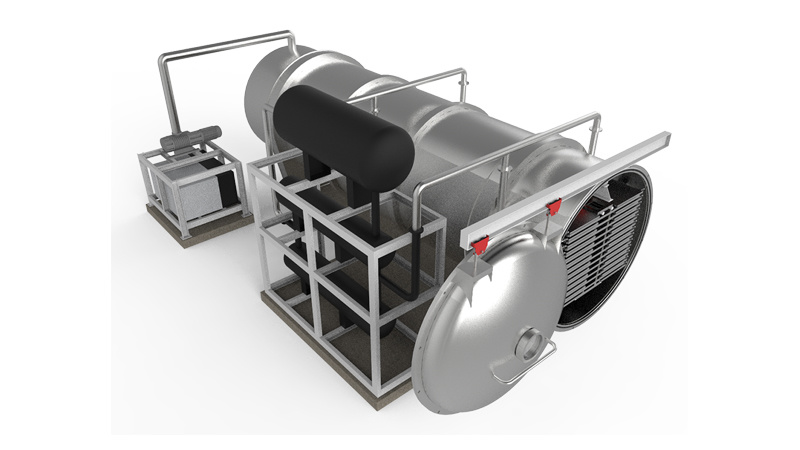

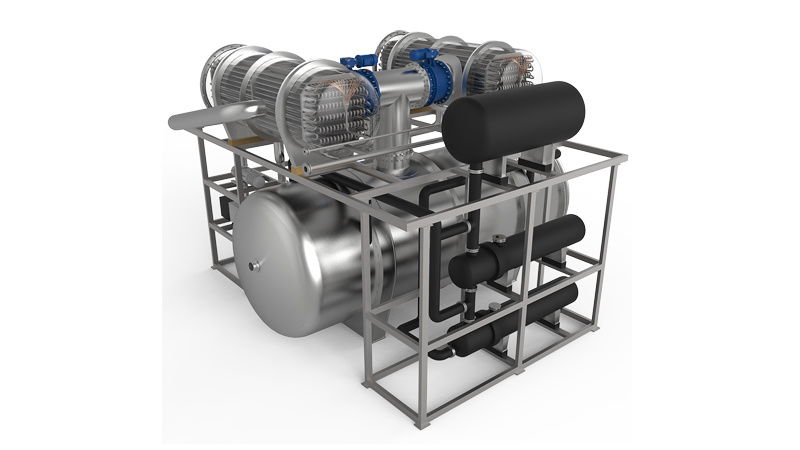

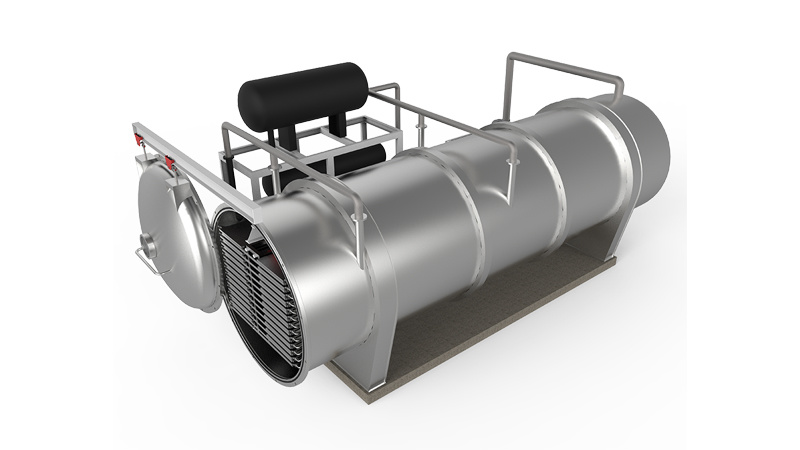

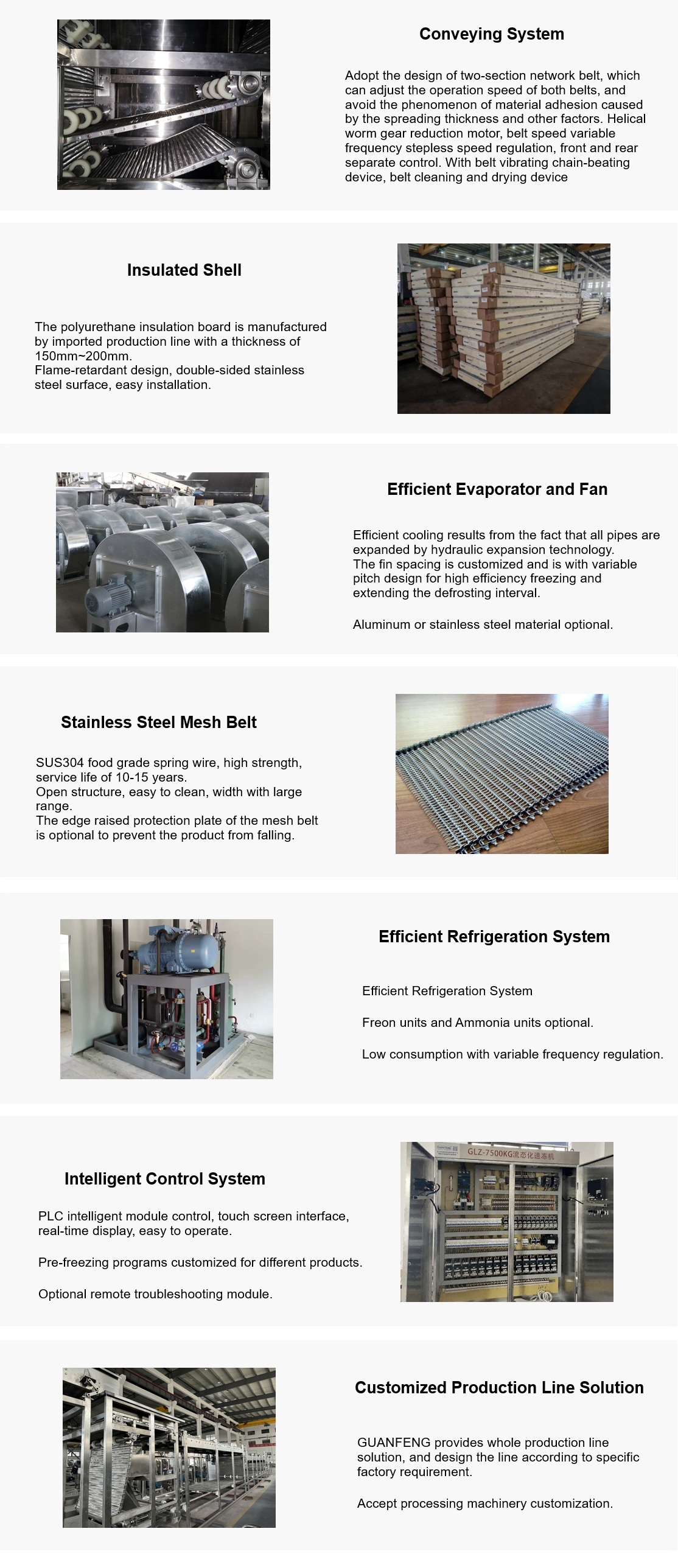

The IQF quick frozen machine is a highly efficient freezing equipment favored in the food processing industry, which uses advanced IQF technology to successfully retain the original form, texture and unique flavor of food by rapidly reducing the temperature.<br> It is suitable for a wide variety of food products, including but not limited to fresh vegetables, fruits, quick - frozen dumplings, shrimps, and various small - sized foods.

IQF Quick Frozen Machine Introduction:

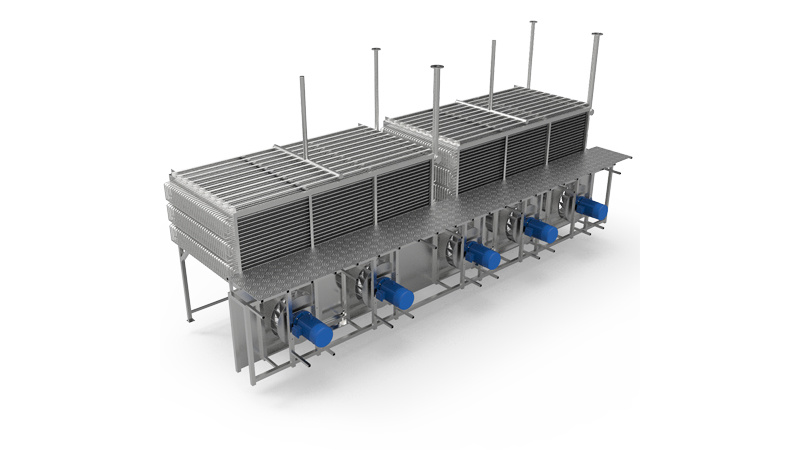

Fluidized IQF freezer freezes materials quickly and evenly through fluidization technology. It adopts a two-section mesh belt design, which can adjust the running speed of the two sections of mesh belts to avoid the phenomenon of material adhesion caused by factors such as the thickness of the fabric. It is suitable for various foods, including but not limited to fresh vegetables, fruits, frozen dumplings, shrimp and various small foods.

IQF Quick Frozen Machine Video:

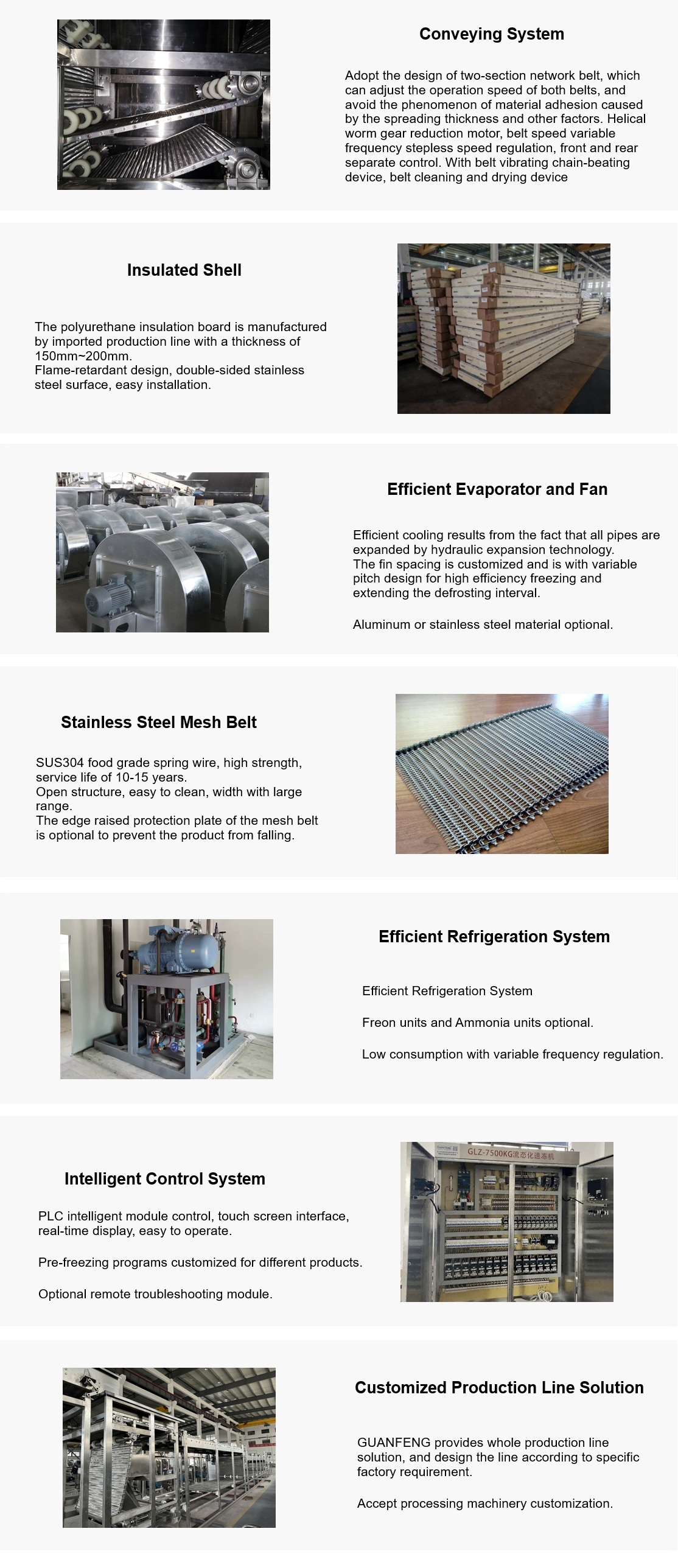

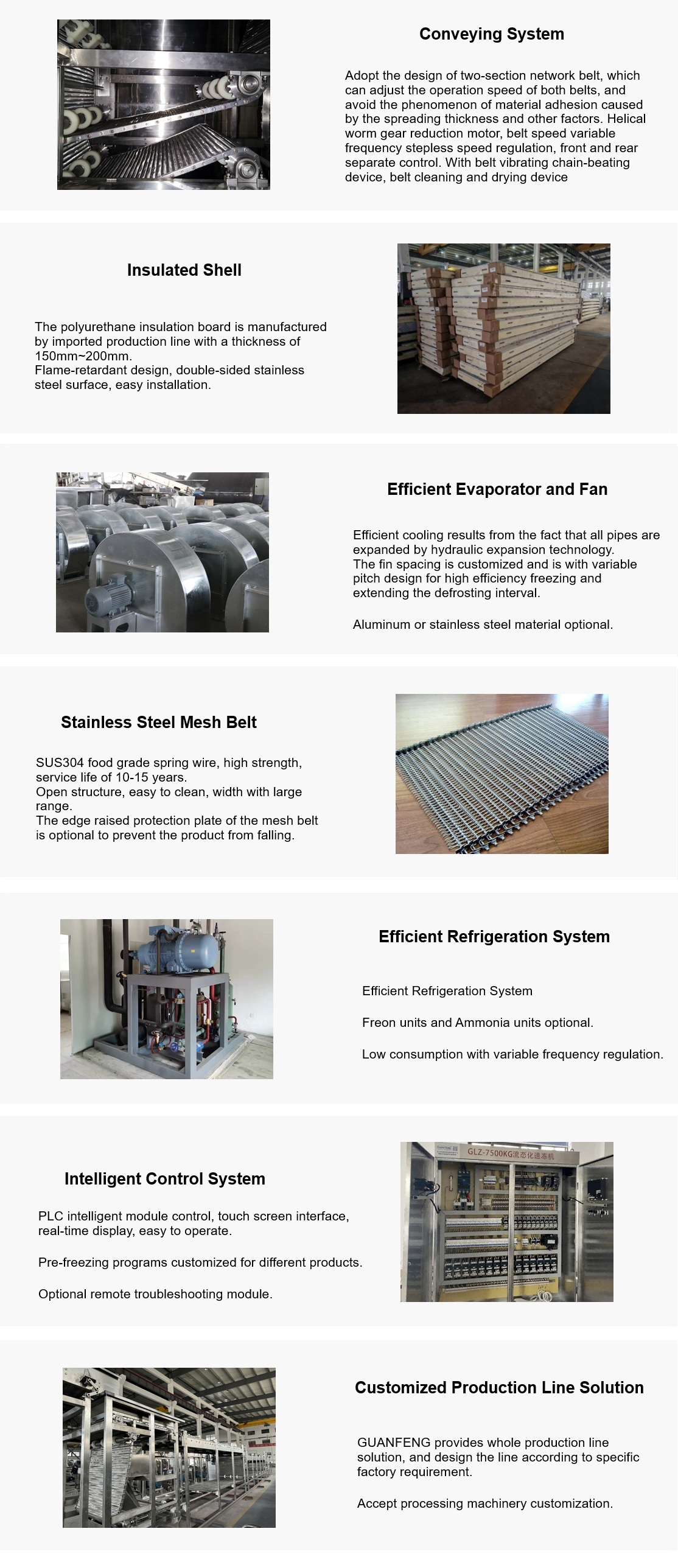

IQF Quick Frozen Machine Parameter:

Model

GLZ-1.0

GLZ-1.5

GLZ-2.0

GLZ-3.0

GLZ-3.0

Capacity(kg/h)

500

1000

1500

2000

3000

Overall dimensions(m)

7.0*3.8*4.05

8.0*4.5*4.05

10.0*4.5*4.05

11.04*4.5*4.05

14.5*4.5*4.05

Length of freezing room(m)

5.0

6.0

8.0

9.0

12.5

Inlet material temperature(℃)

+15

Outlet material temperature(℃)

-18

Freezing temperature(℃)

≤-33

Freezing time(min)

4-40(variable frequency regulation)

Refrigerant

R22/R404A/R717

Cold Consumption(kw)

95

165

245

325

490

Installation Power(kw)

30.9

46.3

61.4

74.2

101.7

-

-

IQF Quick Frozen Machine Configuration

Freezing time

8~40min

Inlet temperature

+15℃

Outlet temperature

-18℃

freezer temperature

<-35℃

Refrigerant

Freon, Ammonia, CO2

Defrosting method

Water/Air/Hot gas defrosting

Control panel

PLC

Heat preservation library

Double-sided stainless steel polyurethane insulation

Hot Tags:

GUANFENG FOOD MACHINERY

Product

Applications

Variety Fruits & Vegetables

GUANFENG freeze dryers can preserve the natural color, flavor, and nutritional value of various fruits and vegetables, making them convenient for long - term storage and rehydration.

Meat Products

To remove moisture from meat products, extending their shelf life while maintaining the texture and taste, suitable for a wide range of meat types

Ready-to-Eat Products

Frozen foods such as French fries, tangyuan (glutinous rice balls), and steamed buns are also processed using fluidized bed quick freezers. This technology ensures that ready-to-eat products maintain their taste and nutrition during freezing, convenient for consumers to enjoy at any time.

GUANFENG FOOD MACHINERY

Product

Recommendation

GUANFENG specializes in customizing production line solution. We are committed to providing the Turn-key freeze drying projects.

Pet Food Freeze Drying Equipment

GUANFENG specializes in crafting customized solutions, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

Tea Vacuum Freeze Drying Machine

Chicken Breast Lyophilization Machine

The capacity for this type is normally about 50kg-100kg per batch.

Get

A Quote

Please leave your email address, our professionals will contact you as soon as possible!

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.