BLOG

Focus on hot topics, real-time dynamics

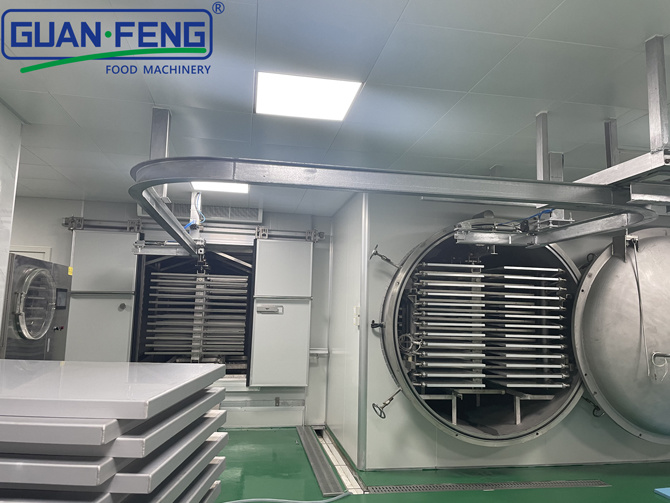

Understanding Vacuum Freeze Dryers: A Comprehensive Guide for Industrial Professionals

Vacuum freeze dryers, commonly referred to as lyophilizers, play a crucial role in the field of industrial drying equipment. These machines are specifically designed to remove moisture from sensitive materials by utilizing a process that involves freezing and sublimation, making them ideal for products that require retention of their original structure, flavor, and nutritional value.

The operational principle of a vacuum freeze dryer begins with the freezing of the product at low temperatures, typically between -40°C and -80°C. This step is essential as it preserves the cellular structure of the material, allowing for minimal damage during the drying process. Once the product is frozen, a vacuum is applied to lower the pressure within the drying chamber. This environment facilitates sublimation, where ice transitions directly from a solid to a vapor state without passing through a liquid form.

One of the significant advantages of vacuum freeze drying is its ability to produce high-quality dried products. This method is particularly advantageous for heat-sensitive items, such as pharmaceuticals, food products, and biological samples, where traditional drying methods may alter their properties. By maintaining low temperatures throughout the process, vacuum freeze dryers help retain the original flavor, color, and nutritional content, which is essential in food preservation and pharmaceuticals.

In addition to preserving product quality, vacuum freeze dryers offer a range of applications across various industries. In the food sector, they are utilized for creating freeze-dried fruits, vegetables, and meals that have extended shelf lives without the need for preservatives. In pharmaceuticals, they are crucial for the preparation of stable drugs and vaccines that need precise moisture control. Similarly, in the biotechnology field, freeze dryers are employed to preserve sensitive biological materials, ensuring they remain viable for future research and applications.

When considering a vacuum freeze dryer for your industrial needs, it is important to evaluate factors such as chamber size, drying capacity, and energy efficiency. Additionally, understanding the specific requirements of your materials will aid in selecting the right model that meets your operational goals.

In conclusion, vacuum freeze dryers represent a sophisticated solution for industries requiring effective moisture removal while preserving product integrity. Their unique drying process, versatility across applications, and ability to maintain product quality make them an indispensable asset in modern industrial drying technologies. By investing in vacuum freeze drying technology, professionals can enhance their production capabilities and ensure they meet the demands of market quality standards.

The operational principle of a vacuum freeze dryer begins with the freezing of the product at low temperatures, typically between -40°C and -80°C. This step is essential as it preserves the cellular structure of the material, allowing for minimal damage during the drying process. Once the product is frozen, a vacuum is applied to lower the pressure within the drying chamber. This environment facilitates sublimation, where ice transitions directly from a solid to a vapor state without passing through a liquid form.

One of the significant advantages of vacuum freeze drying is its ability to produce high-quality dried products. This method is particularly advantageous for heat-sensitive items, such as pharmaceuticals, food products, and biological samples, where traditional drying methods may alter their properties. By maintaining low temperatures throughout the process, vacuum freeze dryers help retain the original flavor, color, and nutritional content, which is essential in food preservation and pharmaceuticals.

In addition to preserving product quality, vacuum freeze dryers offer a range of applications across various industries. In the food sector, they are utilized for creating freeze-dried fruits, vegetables, and meals that have extended shelf lives without the need for preservatives. In pharmaceuticals, they are crucial for the preparation of stable drugs and vaccines that need precise moisture control. Similarly, in the biotechnology field, freeze dryers are employed to preserve sensitive biological materials, ensuring they remain viable for future research and applications.

When considering a vacuum freeze dryer for your industrial needs, it is important to evaluate factors such as chamber size, drying capacity, and energy efficiency. Additionally, understanding the specific requirements of your materials will aid in selecting the right model that meets your operational goals.

In conclusion, vacuum freeze dryers represent a sophisticated solution for industries requiring effective moisture removal while preserving product integrity. Their unique drying process, versatility across applications, and ability to maintain product quality make them an indispensable asset in modern industrial drying technologies. By investing in vacuum freeze drying technology, professionals can enhance their production capabilities and ensure they meet the demands of market quality standards.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.