BLOG

Focus on hot topics, real-time dynamics

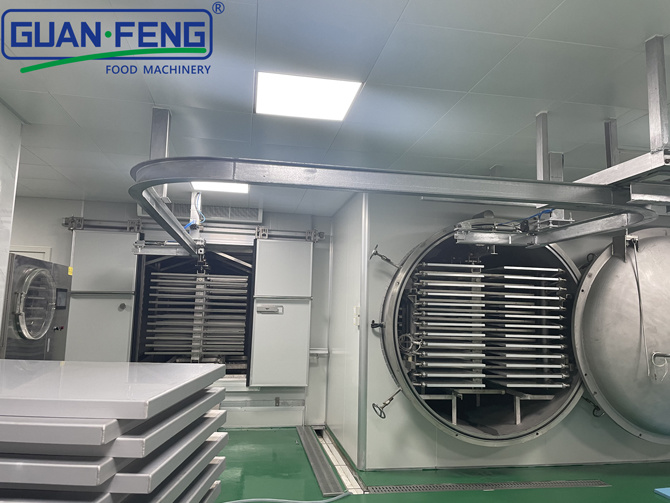

Innovative Uses of Freeze Dryers in the Food Processing Sector

Innovative Uses of Freeze Dryers in the Food Processing Sector

Introduction to Freeze Drying Technology

The food processing industry has continuously evolved, adopting innovative technologies to improve product quality and shelf life. Among these advancements, **freeze drying** stands out as a transformative method that preserves foods while maintaining their essential nutrients, flavors, and textures. This article delves into the innovative uses of freeze dryers in the food processing sector, exploring how this technology shapes the future of food preservation and product development.

The Science Behind Freeze Drying

To understand the innovative applications of freeze dryers, it is essential to grasp the science behind freeze drying. This technique, also known as **lyophilization**, involves the removal of moisture from food products in two primary stages: freezing and sublimation.

Freezing Process

The first step in freeze drying involves rapidly freezing the food at extremely low temperatures, typically between -50°C and -80°C. This process forms ice crystals within the food, effectively locking in its structure and taste.

Sublimation Stage

Following freezing, the pressure is lowered, allowing the ice to convert directly into vapor without passing through the liquid phase. This stage is critical, as it enables the food to retain its shape and nutritional profile while removing up to 98% of its moisture content.

Benefits of Freeze Drying

The benefits of freeze drying are numerous, making it a preferred choice for food manufacturers. Notably, freeze-dried products have:

- **Extended Shelf Life**: Freeze-dried foods can last for years without refrigeration, making them ideal for emergency supplies and long-term storage.

- **Retained Nutritional Value**: Unlike other preservation methods, freeze drying preserves most vitamins, minerals, and flavors, ensuring that the food remains healthy and delicious.

- **Lightweight and Portable**: The removal of moisture creates lightweight products, making them convenient for storage and transport.

Innovative Applications in the Food Processing Sector

As food manufacturers seek to meet consumer demands for quality and convenience, freeze drying proves to be an invaluable asset. Here, we explore several innovative applications of freeze dryers in the food processing sector.

1. Preservation of Fruits and Vegetables

Freeze drying has revolutionized the way fruits and vegetables are preserved. This method effectively retains the color, flavor, and nutritional benefits of fresh produce. For instance, freeze-dried strawberries maintain their vibrant hue and can be rehydrated for use in smoothies, cereals, and baked goods. Similarly, freeze-dried vegetables, like peas and carrots, provide a nutritious addition to soups and stews without compromising on taste.

2. Creating Gourmet Snacks

In recent years, the popularity of gourmet snacks has surged, with freeze-dried foods taking center stage. Products like freeze-dried fruit chips and vegetable crisps offer a crunchy, flavorful alternative to traditional snacks. These products cater to health-conscious consumers seeking nutritious options without added preservatives or unhealthy fats.

3. Enhancing Culinary Experiences

Professional chefs and home cooks alike are embracing freeze-dried ingredients to elevate their dishes. Freeze-dried herbs, for example, retain their potent flavors and aromas, allowing chefs to incorporate them effortlessly into recipes. Additionally, freeze-dried sauces and broths can be rehydrated for instant flavor enhancements in various culinary applications.

4. Ready-to-Eat Meals for Outdoor Activities

Outdoor enthusiasts and emergency preparedness consumers increasingly rely on freeze-dried meals for their convenience and longevity. Freeze-dried backpacking meals require minimal preparation—just add hot water, and they are ready to eat. This innovation has made food storage and meal preparation for camping trips or disaster preparedness more accessible and sustainable.

5. Food Waste Reduction

Freeze drying plays a crucial role in reducing food waste in the industry. By preserving surplus produce and ingredients that might otherwise go to waste, manufacturers can create freeze-dried products that maintain quality and marketability. This sustainable approach not only benefits the environment but also enhances profitability.

Challenges and Considerations in Freeze Drying

While freeze drying presents numerous advantages, it is essential to consider the challenges associated with this technology.

1. Initial Investment and Operating Costs

Setting up a freeze drying operation can be costly, requiring significant investment in specialized equipment. Additionally, the energy costs associated with the freeze-drying process can be higher compared to traditional preservation methods.

2. Quality Control and Consistency

Ensuring consistent quality in freeze-dried products can be challenging. Factors such as moisture levels, temperature fluctuations, and product composition can impact the final product. Implementing strict quality control measures is vital for maintaining product integrity.

3. Consumer Perception and Education

Despite the benefits, some consumers may have misconceptions about freeze-dried foods. Educating consumers about the advantages of freeze drying and addressing concerns regarding texture and flavor is crucial for market acceptance.

Future Trends in Freeze Drying Technology

As the food processing industry continues to evolve, several trends are emerging in freeze drying technology.

1. Customization and Product Development

Future advancements in freeze drying will likely focus on the customization of products to meet specific consumer needs. This includes the development of tailored freeze-dried snacks, meals, and ingredients that cater to dietary preferences and restrictions.

2. Sustainable Practices

The food industry is increasingly shifting towards sustainable practices, and freeze drying aligns well with this movement. Innovations aimed at improving energy efficiency and reducing waste during the freeze-drying process will likely gain traction.

3. Integration of Technology

The integration of smart technology and data analytics into freeze drying processes will enable manufacturers to optimize production efficiency and ensure consistent quality. Real-time monitoring of temperature and pressure can lead to improved outcomes and reduced operational costs.

FAQs About Freeze Dryers in the Food Processing Sector

1. What foods are best suited for freeze drying?

Freeze drying works well for a variety of foods, including fruits, vegetables, meats, and meals. Foods with high water content, such as berries and leafy greens, typically yield excellent results.

2. How does freeze drying affect the taste of food?

Freeze drying retains most of the food's original flavor and aroma, often enhancing the taste. When rehydrated, the food typically regains its fresh flavor profile.

3. Is freeze-dried food healthy?

Yes, freeze-dried foods maintain their nutritional value, with most vitamins and minerals preserved. They are often considered healthier than foods preserved using other methods.

4. How long can freeze-dried foods be stored?

Freeze-dried foods can last for several years when stored in a cool, dark place. Proper packaging, such as vacuum sealing, can significantly extend their shelf life.

5. Can I freeze dry food at home?

Yes, home freeze dryers are available for consumers. However, they require a significant financial investment and proper knowledge to operate effectively.

Conclusion

The innovative uses of freeze dryers in the food processing sector are reshaping how we preserve and enjoy food. From enhancing culinary experiences to reducing food waste, the benefits of this technology are vast and impactful. As we continue to explore the potential of freeze drying, we can expect to see even more exciting developments that cater to the evolving demands of consumers. Embracing this technology not only enhances product quality but also supports sustainability in the food industry, paving the way for a more efficient and environmentally friendly future in food processing.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.