BLOG

Focus on hot topics, real-time dynamics

Step-by-Step Process of Food Freeze Drying Explained: A Comprehensive Guide

Step-by-Step Process of Food Freeze Drying Explained

Introduction to Freeze Drying: What You Need to Know

Freeze drying, also known as lyophilization or cryodesiccation, is a process that removes moisture from food, preserving its structure and nutritional content. This innovative preservation technique has gained popularity in the food industry, especially for items like fruits, vegetables, and meals. In this article, we will walk you through the step-by-step process of food freeze drying, ensuring you understand each phase and its significance.

The Science Behind Freeze Drying: How It Works

To appreciate the freeze drying process, it’s essential to grasp the science that powers it. Freeze drying involves three primary stages: freezing, primary drying (sublimation), and secondary drying (desorption).

Freezing: The Initial Stage of Preservation

During the freezing phase, food is cooled rapidly to temperatures below its freezing point, resulting in the formation of ice crystals. This crucial step ensures that the cellular structure of the food remains intact. When done correctly, the ice crystals form in a way that minimizes damage to the food’s cells, preserving its flavor and nutrients.

Primary Drying (Sublimation): The Heart of the Freeze Drying Process

In this stage, the frozen food is placed under a vacuum. The low pressure causes the ice to change directly from a solid to a gas in a process called sublimation. This stage is critical because it effectively removes about 95% of the water content in food while maintaining its original structure.

Secondary Drying (Desorption): Finalizing the Process

Once the primary drying is complete, secondary drying begins. This phase aims to eliminate any remaining moisture to ensure the food has an extended shelf life. The process involves gently raising the temperature and lowering the pressure, allowing bound moisture to evaporate. The result is a shelf-stable product ready for packaging and consumption.

Essential Equipment for Freeze Drying: What You’ll Need

Understanding the equipment required for freeze drying is vital for anyone looking to delve into this technique. Here’s a rundown of the primary components you’ll need:

Freeze Dryer: The Heart of the Operation

A freeze dryer is the most critical piece of equipment. Commercial models vary in size and capacity, catering to both home and industrial use. When selecting a freeze dryer, consider factors such as the volume of food you plan to process and your budget.

Vacuum Pump: Creating the Perfect Environment

A vacuum pump is essential for creating the low-pressure environment necessary during the primary drying phase. A high-quality pump ensures efficient moisture removal and energy efficiency.

Temperature Control System: Precision is Key

Temperature control systems allow precise regulation of the freeze dryer’s temperature during the entire process. Consistent temperature management is crucial for achieving optimal results.

Packaging Materials: Keeping the Product Fresh

Post-drying, proper packaging materials must be employed to keep the moisture out and preserve the quality of the freeze-dried food. Mylar bags, vacuum-sealed containers, and oxygen absorbers are commonly used.

The Step-by-Step Process of Freeze Drying Food

Now that we've covered the basics of freeze drying and the equipment needed, let's delve into the step-by-step process of freeze drying food.

Step 1: Selecting the Right Food

Selecting food with low moisture content is essential for optimal freeze-drying results. Fruits, vegetables, cooked meals, and herbs work well, while items like dairy and high-fat foods may not yield favorable outcomes.

Step 2: Pre-Treatment of Food

Some foods benefit from pre-treatment prior to freeze drying. For example, blanching vegetables can help preserve color and nutrients. Slicing food into uniform sizes can also ensure even drying.

Step 3: Freezing the Food

Once prepped, the food must be frozen quickly to prevent large ice crystals from forming. This can be done in a conventional freezer or, for faster results, a blast freezer.

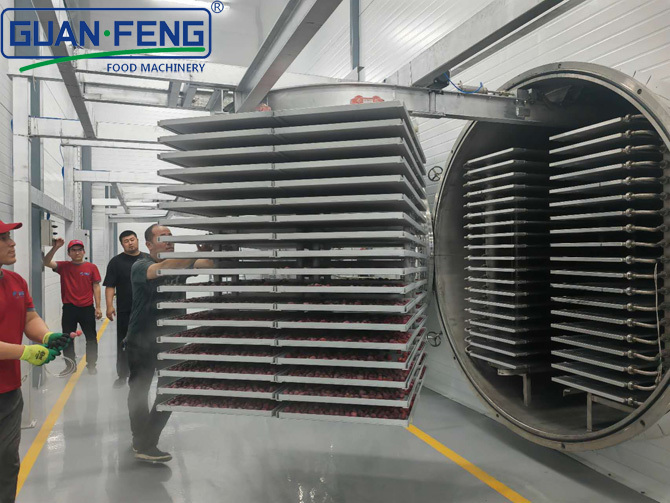

Step 4: Loading the Freeze Dryer

After the food is adequately frozen, it is loaded into the freeze dryer trays. Ensure there’s enough space for air to circulate around the food for efficient drying.

Step 5: Initiating the Freeze Drying Process

Start the freeze dryer and monitor the temperature and pressure settings. The machine will automatically adjust these factors during the process to ensure efficient moisture removal.

Step 6: Monitoring the Drying Process

It's crucial to monitor the drying process closely, especially for the first few times. This ensures that everything is functioning correctly, and the food is drying as expected.

Step 7: Testing for Doneness

After the primary drying phase, check if the food is completely dry. For fruits, they should be crispy, while vegetables should be brittle. If they feel moist, further drying is necessary.

Step 8: Packaging the Freeze-Dried Food

Once the freeze-dried food is ready, package it in airtight, moisture-proof containers to ensure it remains shelf-stable. Label the packages with the date and contents for easy identification.

Step 9: Storing Freeze-Dried Food

Store the packaged food in a cool, dark place away from heat sources to maximize shelf life. Properly dried and packaged foods can last for years without significant loss of quality.

Benefits of Freeze Drying Food

The advantages of freeze drying are numerous and impactful, making it a preferred method for many. Here are some compelling benefits to consider:

Long Shelf Life

Freeze-dried foods can last for up to 25 years if stored correctly, making them ideal for emergency preparedness and long-term food storage.

Preservation of Nutrients and Flavor

Because freeze drying removes moisture without applying excessive heat, the nutrient content and flavor of the food are well preserved. This results in delicious and nutritious meals when rehydrated.

Lightweight and Convenient

Freeze-dried foods are significantly lighter than their fresh counterparts, making them easy to transport. This is particularly advantageous for campers, hikers, and those in need of lightweight meal options.

Versatile Applications

Freeze-dried foods can be utilized in various settings, from home cooking to pre-packaged meals for emergency kits. The versatility allows for a wide range of culinary possibilities.

Common Misconceptions About Freeze Drying

Despite its benefits, several misconceptions exist about freeze drying. Let’s address some of the most common ones.

Misconception 1: Freeze-Dried Food Lacks Flavor

On the contrary, freeze-dried food retains much of its original flavor. In fact, many people find that the rehydrated product tastes just as good, if not better, than fresh food due to the concentration of flavors.

Misconception 2: Freeze Drying is Complicated and Time-Consuming

While the process requires specific equipment and steps, modern freeze dryers simplify the process significantly. Once the food is prepared and loaded, the machine does much of the work.

Misconception 3: Freeze-Dried Food is Unhealthy

Freeze-dried food maintains its nutritional value and can be a healthy addition to any diet. It's crucial to select high-quality ingredients for the best results.

FAQs About Freeze Drying Food

1. How long does the freeze-drying process take?

The duration of the freeze-drying process depends on the type and quantity of food, but it typically takes between 24 to 48 hours.

2. Can I freeze dry leftovers?

Yes, leftover meals can be freeze-dried as long as they contain minimal moisture and are properly prepared before the process.

3. What types of food are not suitable for freeze drying?

Foods that are high in fat, such as cheese and butter, do not freeze-dry well and can spoil when stored.

4. Do I need to rehydrate freeze-dried food before eating?

Yes, freeze-dried foods need to be rehydrated with water before consumption, but some snacks can be eaten as-is.

5. How can I store freeze-dried food to maximize shelf life?

Store freeze-dried food in airtight containers or vacuum-sealed bags in a cool, dark place to ensure maximum shelf life.

Conclusion

The step-by-step process of food freeze drying is a fascinating blend of science and culinary innovation. By understanding the methodology and benefits, you can appreciate how this technique has revolutionized food preservation. Whether you’re a home cook, a survivalist, or just someone interested in food technology, mastering freeze drying opens up a world of possibilities. From long-lasting pantry staples to nutrient-packed meals, the advantages of freeze-dried foods are undeniable, making it a valuable skill in today’s fast-paced world.

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.