BLOG

Focus on hot topics, real-time dynamics

Understanding Vacuum Freeze Drying Machines: An Essential Guide for Professionals

Vacuum freeze drying machines, also known as lyophilizers, are innovative devices designed to remove moisture from products while preserving their structure and nutrients. This process, known as freeze drying, involves freezing the material and then reducing the pressure to allow the frozen water to sublimate directly from ice to vapor. The process typically occurs in a vacuum chamber, where a series of specific temperature and pressure conditions are maintained to ensure optimal results.

One of the primary advantages of using vacuum freeze drying machines is the preservation of the product's quality. This method is particularly beneficial for sensitive materials, such as pharmaceuticals, food products, and biological samples. Conventional drying methods often lead to significant losses in flavor, aroma, and nutritional value due to high temperatures and prolonged exposure to air. In contrast, freeze drying maintains the integrity of these products, making it an ideal choice for industries where quality is paramount.

Another significant benefit of this technology is the extended shelf life it provides. By removing moisture, vacuum freeze drying machines inhibit the growth of microorganisms and enzymatic reactions that can lead to spoilage. This feature is especially valuable in the food industry, where products can be stored for extended periods without refrigeration, enabling better distribution and reduced waste.

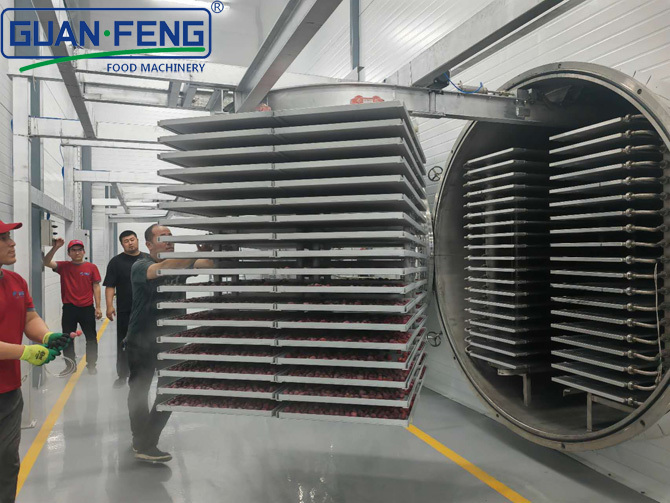

In terms of operation, vacuum freeze drying machines typically consist of several key components, including a freezing unit, a vacuum chamber, and a condensation unit. The freezing unit rapidly cools the product, while the vacuum chamber creates the low-pressure environment necessary for sublimation. The condensation unit collects the vapor, which can then be removed or reprocessed.

The applications of vacuum freeze drying technology are vast and diverse. In the pharmaceutical industry, lyophilization is commonly employed for the preservation of vaccines, antibiotics, and other heat-sensitive compounds. In the food sector, freeze-dried fruits and vegetables have gained popularity for their lightweight nature and concentrated flavors, making them appealing for both consumers and manufacturers. Additionally, vacuum freeze drying is increasingly used in the biotechnology field for the preservation of microbial cultures and enzymes.

As industries continue to prioritize efficiency and product quality, the demand for vacuum freeze drying machines is expected to grow. These machines not only enhance the preservation and shelf life of products but also align with sustainable practices by reducing waste.

In conclusion, vacuum freeze drying machines represent a significant advancement in drying technology, offering numerous benefits across various industries. Understanding their operation and advantages can help professionals make informed decisions about their application, ultimately leading to improved product quality and sustainability.

One of the primary advantages of using vacuum freeze drying machines is the preservation of the product's quality. This method is particularly beneficial for sensitive materials, such as pharmaceuticals, food products, and biological samples. Conventional drying methods often lead to significant losses in flavor, aroma, and nutritional value due to high temperatures and prolonged exposure to air. In contrast, freeze drying maintains the integrity of these products, making it an ideal choice for industries where quality is paramount.

Another significant benefit of this technology is the extended shelf life it provides. By removing moisture, vacuum freeze drying machines inhibit the growth of microorganisms and enzymatic reactions that can lead to spoilage. This feature is especially valuable in the food industry, where products can be stored for extended periods without refrigeration, enabling better distribution and reduced waste.

In terms of operation, vacuum freeze drying machines typically consist of several key components, including a freezing unit, a vacuum chamber, and a condensation unit. The freezing unit rapidly cools the product, while the vacuum chamber creates the low-pressure environment necessary for sublimation. The condensation unit collects the vapor, which can then be removed or reprocessed.

The applications of vacuum freeze drying technology are vast and diverse. In the pharmaceutical industry, lyophilization is commonly employed for the preservation of vaccines, antibiotics, and other heat-sensitive compounds. In the food sector, freeze-dried fruits and vegetables have gained popularity for their lightweight nature and concentrated flavors, making them appealing for both consumers and manufacturers. Additionally, vacuum freeze drying is increasingly used in the biotechnology field for the preservation of microbial cultures and enzymes.

As industries continue to prioritize efficiency and product quality, the demand for vacuum freeze drying machines is expected to grow. These machines not only enhance the preservation and shelf life of products but also align with sustainable practices by reducing waste.

In conclusion, vacuum freeze drying machines represent a significant advancement in drying technology, offering numerous benefits across various industries. Understanding their operation and advantages can help professionals make informed decisions about their application, ultimately leading to improved product quality and sustainability.

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.