BLOG

Focus on hot topics, real-time dynamics

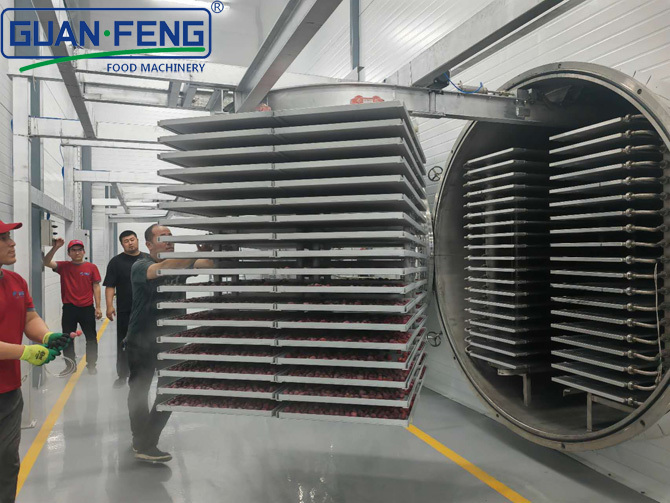

Understanding Lyophilizer Machines: A Key to Efficient Freeze-Drying in Life Sciences

Lyophilizer machines, commonly known as freeze dryers, play a pivotal role in the preservation of biological materials, pharmaceuticals, and various sensitive compounds within the life sciences sector. The process of lyophilization, or freeze-drying, involves removing moisture from a product after it has been frozen, leading to a stable and shelf-stable product without the need for refrigeration. This article delves into the principles, applications, and advantages of using lyophilizer machines in contemporary research and production settings.

The operation of a lyophilizer machine is based on three primary stages: freezing, primary drying, and secondary drying. Initially, the sample is frozen at low temperatures, which allows the water contained within to solidify. Following this, under vacuum conditions, sublimation occurs where ice transitions directly from solid to vapor, effectively removing moisture without passing through the liquid phase. The final phase involves lowering the remaining moisture content to achieve the desired stability and shelf life of the product.

In the realm of life sciences, the applications of lyophilizer machines are vast. They are extensively used for the preservation of biological samples, including proteins, enzymes, vaccines, and cultures, which are often sensitive to heat and moisture. By using lyophilization, researchers can ensure the viability of these samples over extended periods, significantly aiding in storage and transportation processes. Furthermore, lyophilization is essential in the pharmaceutical industry for the manufacturing of a variety of drugs, enhancing their stability and enabling ease of use in clinical settings.

Beyond their preservation capabilities, lyophilizer machines offer numerous benefits. One major advantage is the improved solubility of the rehydrated product, as the porous structure created during the freeze-drying process allows for rapid absorption of liquids upon reconstitution. Additionally, lyophilization helps maintain the integrity of sensitive compounds, preserving their biological activity and efficacy, which is crucial in experimental and therapeutic applications.

Moreover, advancements in lyophilizer technology have led to increased automation and efficiency, allowing for precise control over temperature and pressure conditions throughout the drying process. This ensures consistent quality and reproducibility, which are essential factors in scientific research and clinical applications.

In conclusion, lyophilizer machines are indispensable in the life sciences industry, facilitating the preservation of sensitive materials through a reliable and effective freeze-drying process. By understanding their operational principles and benefits, professionals in the field can leverage these machines to enhance their research and product development efforts, ensuring high-quality outcomes for various applications.

The operation of a lyophilizer machine is based on three primary stages: freezing, primary drying, and secondary drying. Initially, the sample is frozen at low temperatures, which allows the water contained within to solidify. Following this, under vacuum conditions, sublimation occurs where ice transitions directly from solid to vapor, effectively removing moisture without passing through the liquid phase. The final phase involves lowering the remaining moisture content to achieve the desired stability and shelf life of the product.

In the realm of life sciences, the applications of lyophilizer machines are vast. They are extensively used for the preservation of biological samples, including proteins, enzymes, vaccines, and cultures, which are often sensitive to heat and moisture. By using lyophilization, researchers can ensure the viability of these samples over extended periods, significantly aiding in storage and transportation processes. Furthermore, lyophilization is essential in the pharmaceutical industry for the manufacturing of a variety of drugs, enhancing their stability and enabling ease of use in clinical settings.

Beyond their preservation capabilities, lyophilizer machines offer numerous benefits. One major advantage is the improved solubility of the rehydrated product, as the porous structure created during the freeze-drying process allows for rapid absorption of liquids upon reconstitution. Additionally, lyophilization helps maintain the integrity of sensitive compounds, preserving their biological activity and efficacy, which is crucial in experimental and therapeutic applications.

Moreover, advancements in lyophilizer technology have led to increased automation and efficiency, allowing for precise control over temperature and pressure conditions throughout the drying process. This ensures consistent quality and reproducibility, which are essential factors in scientific research and clinical applications.

In conclusion, lyophilizer machines are indispensable in the life sciences industry, facilitating the preservation of sensitive materials through a reliable and effective freeze-drying process. By understanding their operational principles and benefits, professionals in the field can leverage these machines to enhance their research and product development efforts, ensuring high-quality outcomes for various applications.

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.