BLOG

Focus on hot topics, real-time dynamics

Lyophilization Machines: Key Features to Look For in Life Science Applications

Lyophilization Machines: Key Features to Look For

Lyophilization, or freeze-drying, is a preservation technique widely utilized in the life sciences to extend the shelf-life of sensitive products, such as pharmaceuticals, biologics, and laboratory samples. As demand increases, so does the need for high-quality lyophilization machines. In this article, we will explore the essential features you should consider when investing in a lyophilization machine.

Table of Contents

- Understanding Lyophilization

- Importance of Lyophilization Machines in Life Sciences

- Key Features of Lyophilization Machines

- Design and Configuration

- Temperature Control Systems

- Vacuum Systems

- Control Systems and Software

- Scalability and Capacity

- Energy Efficiency and Sustainability

- Cost-Effectiveness of Lyophilization Machines

- Maintaining and Servicing Your Lyophilization Machine

- Future Trends in Lyophilization Technology

- Conclusion

- FAQs

Understanding Lyophilization

Lyophilization is a sophisticated process that involves the sublimation of water from a frozen product, allowing for the preservation of its structural integrity and biochemical properties. This method is especially crucial in the pharmaceutical and biotech industries, where active ingredients need to remain stable over extended periods. By removing moisture under controlled conditions, lyophilization ensures that products maintain their efficacy, stability, and safety.

Importance of Lyophilization Machines in Life Sciences

Lyophilization machines are pivotal in producing high-quality products in the life sciences sector. They enable the preservation of proteins, vaccines, and other sensitive biological materials. The following points illustrate their critical role:

- **Preservation of Biologic Integrity**: By minimizing the degradation of biologics, lyophilization machines help maintain the efficacy of critical products.

- **Extended Shelf Life**: Preventing moisture-induced spoilage allows for longer storage durations, reducing waste and improving supply chain efficiency.

- **Ease of Reconstitution**: Lyophilized products can be easily reconstituted, making them convenient for end-users.

- **Scalable Solutions**: Advanced machines cater to various production scales, from research and development to large-scale manufacturing.

Key Features of Lyophilization Machines

When selecting a lyophilization machine, several key features should be evaluated to ensure optimal performance and suitability for your specific needs.

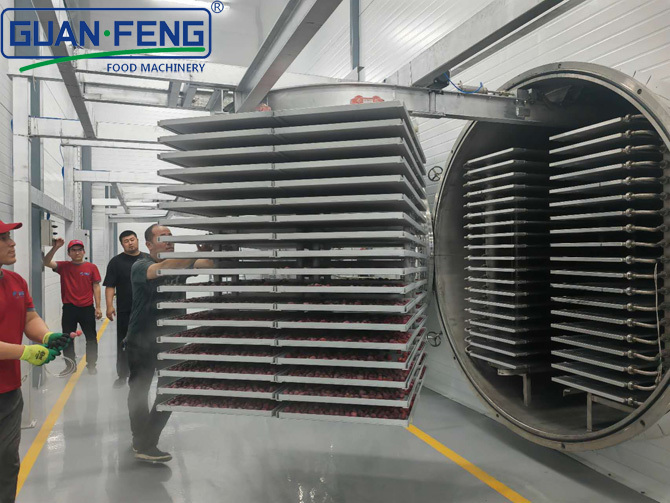

Design and Configuration

The design of a lyophilization machine significantly influences its operational efficiency. Key aspects include:

- **Modular Design**: Machines with modular designs can be adjusted based on production requirements, making them versatile for different applications.

- **Interior Configuration**: The layout of shelves, trays, and the overall chamber should facilitate optimal heat transfer and airflow, which are critical for effective freeze-drying.

Temperature Control Systems

Temperature control is paramount in the lyophilization process. Machines equipped with advanced temperature control systems allow for precise monitoring and adjustment, which is crucial for maintaining product quality. Key features to look for include:

- **Multi-Zone Temperature Control**: Allows for different temperature profiles across shelves, enabling better customization for various products.

- **Real-Time Monitoring**: Real-time data logging helps track temperature fluctuations and ensures that products remain within specified conditions throughout the process.

Vacuum Systems

Effective vacuum systems are essential for the sublimation phase of lyophilization. Consider the following aspects:

- **Efficiency**: Look for machines with high-efficiency vacuum pumps that can achieve low pressures quickly and maintain them consistently.

- **Leak Detection**: Advanced systems come with built-in leak detection mechanisms, ensuring that the vacuum integrity is maintained during the process.

Control Systems and Software

The control system is the brain of the lyophilization machine. An intuitive and robust software interface can significantly enhance operational efficiency. Consider features such as:

- **User-Friendly Interface**: A straightforward control system allows operators to adjust settings and monitor processes easily.

- **Automated Reporting**: Automated system logs and reporting features help in compliance with regulatory standards and facilitate troubleshooting.

Scalability and Capacity

The scalability of a lyophilization machine is crucial, especially for companies anticipating growth or fluctuation in demand. Key considerations include:

- **Batch Size Options**: Flexibility in batch sizes allows for efficient production scaling without requiring a complete system overhaul.

- **Modular Expansion**: Choosing machines that allow for future upgrade options can save costs in the long term.

Energy Efficiency and Sustainability

In today’s environmentally conscious market, energy efficiency is not just a bonus; it is essential. Look for lyophilization machines that feature:

- **Energy-Efficient Designs**: Machines designed to minimize energy consumption can significantly lower operating costs.

- **Sustainable Practices**: Many manufacturers are now focusing on sustainable materials and practices, which can align with your company’s values.

Cost-Effectiveness of Lyophilization Machines

Investing in a lyophilization machine is significant, and understanding the cost-effectiveness is vital:

- **Initial vs. Long-Term Costs**: Assess the initial investment against long-term operational costs, including maintenance, energy consumption, and potential downtime.

- **ROI Evaluation**: Analyze how improved product quality and extended shelf life can translate into higher profits and reduced waste, contributing to a solid return on investment.

Maintaining and Servicing Your Lyophilization Machine

Regular maintenance and timely servicing are crucial to prolong the life of your lyophilization machine. Considerations include:

- **Scheduled Maintenance**: Establishing a routine maintenance schedule can prevent unexpected downtimes and ensure consistent performance.

- **Training and Support**: Verify that the manufacturer provides comprehensive training and accessible customer support to assist with troubleshooting and maintenance.

Future Trends in Lyophilization Technology

As technology evolves, the lyophilization process is also undergoing significant changes. Emerging trends include:

- **Integration of Artificial Intelligence (AI)**: AI can enhance process optimization by analyzing data and predicting outcomes based on historical performance.

- **Smart Manufacturing**: The rise of Industry 4.0 is leading to more connected machines that can communicate data across platforms for better decision-making.

- **Personalized Medicine**: As personalized medicine gains traction, lyophilization machines will need to adapt to smaller, customized batch productions.

Conclusion

Choosing the right lyophilization machine is a critical decision that can significantly impact the quality of your products and the efficiency of your operations. By considering essential features such as design, temperature control, vacuum systems, and scalability, you can select a machine that meets your specific needs. Additionally, prioritizing energy efficiency and sustainability can enhance your operational efficiency while contributing to environmental responsibility. As technology advances, staying informed about the latest trends will help you maintain a competitive edge in the life sciences sector.

FAQs

1. What is the primary function of a lyophilization machine?

The primary function of a lyophilization machine is to remove moisture from sensitive products, preserving their integrity and extending their shelf life.

2. How do I choose the right lyophilization machine for my needs?

Consider factors such as your production scale, product type, temperature control systems, and the machine's efficiency and maintenance requirements.

3. Can lyophilization be used for all types of products?

Not all products are suitable for lyophilization. Products with high fat content or those that do not freeze well may not yield optimal results.

4. What are the benefits of using lyophilization machines in pharmaceuticals?

Lyophilization machines help maintain the potency and stability of pharmaceuticals, extending their shelf life and making them easier to transport and store.

5. How often should a lyophilization machine be serviced?

Regular maintenance schedules should be established, typically recommended every 6 to 12 months, depending on usage and manufacturer guidelines.

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.