BLOG

Focus on hot topics, real-time dynamics

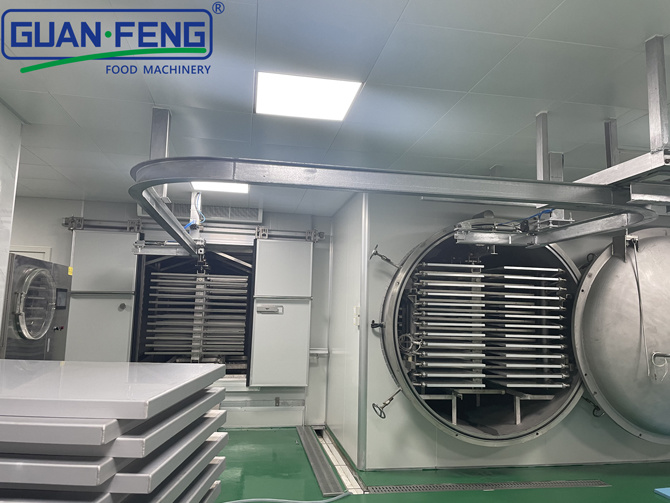

Understanding Lyophilization Machines: Essential Insights for Life Science Professionals

Lyophilization, commonly known as freeze-drying, is a critical process in various fields, particularly in the life sciences. A lyophilization machine is designed to remove moisture from samples by freezing them and then reducing the surrounding pressure to allow the ice to sublimate. This process preserves the integrity of the material, making it an invaluable tool for pharmaceutical companies, research institutions, and biotechnological applications.

One of the primary benefits of a lyophilization machine is its ability to stabilize sensitive biological materials, including proteins, vaccines, and enzymes. These substances often degrade when exposed to moisture or higher temperatures. By utilizing a lyophilization machine, professionals can ensure that these materials retain their functional properties over extended storage periods. This is especially vital in the development of vaccines, where maintaining potency is crucial for efficacy.

In addition to stabilization, lyophilization machines also offer ease of transportation. Once dried, samples become lightweight and less fragile, which facilitates shipping and storage. This is particularly beneficial for companies that need to distribute biological materials globally, as it reduces the risk of spoilage and loss during transit.

When selecting a lyophilization machine, professionals should consider various factors such as chamber size, cooling capacity, and the ability to control vacuum levels. Advanced machines also come with features like automated cycles and real-time monitoring systems, which enhance efficiency and ease of use. These features allow users to optimize the lyophilization process based on the specific characteristics of the materials being processed.

Moreover, the applications of lyophilization machines extend beyond pharmaceuticals. They are also used in the food industry to preserve fruits, vegetables, and ready-to-eat meals without compromising nutritional value. In the production of dietary supplements, lyophilization helps ensure that active ingredients remain effective.

Overall, understanding the functionality and advantages of lyophilization machines is essential for life science professionals. By leveraging this technology, they can improve the quality and longevity of sensitive materials, ultimately supporting advancements in research and healthcare. Whether you are a researcher, a production manager, or a quality control specialist, familiarizing yourself with lyophilization processes and machine capabilities will enhance your operational efficiency and product integrity.

One of the primary benefits of a lyophilization machine is its ability to stabilize sensitive biological materials, including proteins, vaccines, and enzymes. These substances often degrade when exposed to moisture or higher temperatures. By utilizing a lyophilization machine, professionals can ensure that these materials retain their functional properties over extended storage periods. This is especially vital in the development of vaccines, where maintaining potency is crucial for efficacy.

In addition to stabilization, lyophilization machines also offer ease of transportation. Once dried, samples become lightweight and less fragile, which facilitates shipping and storage. This is particularly beneficial for companies that need to distribute biological materials globally, as it reduces the risk of spoilage and loss during transit.

When selecting a lyophilization machine, professionals should consider various factors such as chamber size, cooling capacity, and the ability to control vacuum levels. Advanced machines also come with features like automated cycles and real-time monitoring systems, which enhance efficiency and ease of use. These features allow users to optimize the lyophilization process based on the specific characteristics of the materials being processed.

Moreover, the applications of lyophilization machines extend beyond pharmaceuticals. They are also used in the food industry to preserve fruits, vegetables, and ready-to-eat meals without compromising nutritional value. In the production of dietary supplements, lyophilization helps ensure that active ingredients remain effective.

Overall, understanding the functionality and advantages of lyophilization machines is essential for life science professionals. By leveraging this technology, they can improve the quality and longevity of sensitive materials, ultimately supporting advancements in research and healthcare. Whether you are a researcher, a production manager, or a quality control specialist, familiarizing yourself with lyophilization processes and machine capabilities will enhance your operational efficiency and product integrity.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.