BLOG

Focus on hot topics, real-time dynamics

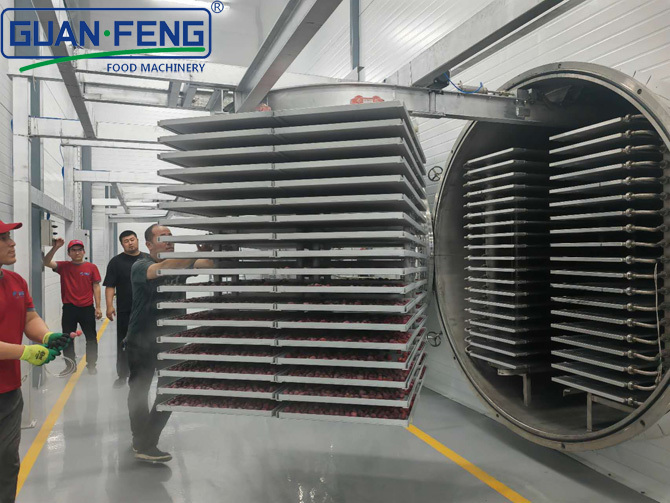

The Environmental Impact of Vacuum Freeze Drying Processes: An In-Depth Analysis

The Environmental Impact of Vacuum Freeze Drying Processes

Vacuum freeze drying, also known as lyophilization, is a widely used technique in the food, pharmaceutical, and biotechnology industries. This method preserves materials by removing moisture under low temperatures and pressure, ensuring the integrity of the product. While vacuum freeze drying offers numerous advantages in product preservation, it also carries environmental impacts that warrant careful examination. In this article, we will explore the environmental implications of vacuum freeze drying processes, delving into energy consumption, emissions, waste management, and sustainable practices.

Understanding Vacuum Freeze Drying: The Basics

To fully grasp the environmental impact of vacuum freeze drying, it is essential to understand its operational principles. The process typically involves three main stages:

1. Freezing

During the initial phase, the product is frozen rapidly to create solid ice. This step is crucial as it influences the final texture and quality of the product after drying.

2. Primary Drying (Sublimation)

In this stage, the pressure is lowered, and heat is applied to transition the ice directly into vapor, effectively removing moisture without damaging the material. This phase is where the drying occurs and can consume significant energy.

3. Secondary Drying (Desorption)

Finally, any remaining moisture is removed by raising the temperature and further reducing pressure. This step ensures that the final product has minimal water content, crucial for maintaining shelf life and quality.

The Energy Consumption Challenge

One of the most pressing environmental concerns related to vacuum freeze drying is its energy consumption. This process requires substantial energy to achieve the low temperatures and vacuum conditions necessary for effective drying.

1. Energy Use in Vacuum Freeze Dryers

Vacuum freeze dryers operate under specific conditions that demand high energy input. The consumption can vary based on the equipment's efficiency, the scale of production, and the materials being processed. On average, freeze drying can consume three to ten times more energy than conventional drying methods.

2. Renewable Energy Solutions

To mitigate the environmental footprint of energy consumption, many industries are exploring renewable energy sources. Implementing solar, wind, or geothermal energy in freeze drying facilities can significantly reduce reliance on fossil fuels, leading to a lower carbon footprint.

Emissions and Air Quality Considerations

The vacuum freeze drying process can also contribute to greenhouse gas emissions. During the operation, various gases may be released into the atmosphere, impacting air quality and contributing to climate change.

1. Emissions from Energy Sources

The type of energy used in freeze drying plays a crucial role in determining the emissions associated with the process. For instance, facilities that rely on fossil fuels will inherently produce more carbon dioxide and related pollutants compared to those using cleaner energy sources.

2. Mitigating Air Quality Impact

Implementing advanced filtration and scrubber systems can help capture and mitigate emissions. These technologies not only enhance air quality but also align with regulatory standards and sustainability goals.

Waste Generation and Management

Waste management is another critical aspect of evaluating the environmental impact of vacuum freeze drying processes. While the process itself primarily produces solid products, there are associated wastes that need careful management.

1. Solid Waste from Products

Depending on the nature of the materials being freeze-dried, there can be significant solid waste generated from non-usable portions. Proper disposal methods, including recycling or composting, can help minimize environmental harm.

2. Wastewater Considerations

In some cases, freeze drying processes involve pre-treatment stages that may generate wastewater. This byproduct must be treated appropriately to prevent contamination of local water sources.

Sustainable Practices in Vacuum Freeze Drying

To counterbalance the environmental effects of vacuum freeze drying, industries are increasingly adopting sustainable practices.

1. Equipment Upgrades and Innovations

Investing in energy-efficient vacuum freeze dryers can drastically reduce energy consumption. New technologies, such as advanced control systems and insulation, improve the efficiency of existing equipment.

2. Lifecycle Assessments

Conducting lifecycle assessments (LCAs) can provide valuable insights into the environmental footprint of vacuum freeze drying. These assessments examine the entire process, from raw material extraction to product disposal, helping identify areas for improvement.

3. Eco-friendly Materials

Using biodegradable and environmentally friendly materials in the freeze drying process can reduce the overall impact on the environment. This includes selecting products that have a lower carbon footprint during their lifecycle.

Case Studies: Environmental Impact in Action

Several industries showcase the practical implications of vacuum freeze drying processes and their environmental impacts.

1. Pharmaceutical Industry

In the pharmaceutical sector, vacuum freeze drying is crucial for preserving sensitive compounds. However, the energy demands and waste generation associated with this process have led companies to explore greener alternatives. For instance, one major pharmaceutical manufacturer reduced their carbon emissions by 30% through energy optimization practices.

2. Food Industry

The food industry has also embraced vacuum freeze drying due to its ability to retain flavors and nutrients. However, concerns over energy consumption have driven advancements in equipment technology. Companies have reported energy savings of up to 40% after upgrading to modern freeze drying systems.

Future Trends in Vacuum Freeze Drying and Sustainability

As industries continue to evolve, the future of vacuum freeze drying appears increasingly focused on sustainability.

1. Integration of AI and IoT

The integration of artificial intelligence (AI) and the Internet of Things (IoT) into vacuum freeze drying processes holds promise for optimizing energy consumption and minimizing waste. Smart monitoring systems can provide real-time data on energy use and operational efficiency.

2. Regulatory Changes and Industry Standards

Regulatory bodies are increasingly emphasizing sustainable practices. Industries must adapt to meet these changing standards, focusing on reducing emissions and enhancing overall sustainability.

FAQs About Vacuum Freeze Drying and Environmental Impact

1. What is the primary environmental concern with vacuum freeze drying?

The main concerns are energy consumption, greenhouse gas emissions, and waste generation associated with the process.

2. How can industries reduce energy consumption in vacuum freeze drying?

Adopting energy-efficient equipment, utilizing renewable energy sources, and optimizing operational practices can help reduce energy usage.

3. Are there regulations governing the environmental impact of freeze drying processes?

Yes, various regulatory frameworks exist to guide industries in minimizing their environmental footprint, focusing on emissions and waste management.

4. Can vacuum freeze drying be considered a sustainable practice?

While it has environmental impacts, adopting sustainable practices and technologies can significantly mitigate its effects, making it more environmentally friendly.

5. What role does lifecycle assessment play in improving vacuum freeze drying processes?

Lifecycle assessments help identify the environmental impact of freeze drying from start to finish, allowing for targeted improvements in sustainability efforts.

Conclusion

In conclusion, the environmental impact of vacuum freeze drying processes is multifaceted, encompassing energy consumption, emissions, and waste generation. While this technique offers significant advantages in preserving product quality, it is essential to balance these benefits with sustainable practices. By investing in energy-efficient technologies, implementing waste management strategies, and adhering to regulatory standards, industries can mitigate the environmental footprint of vacuum freeze drying. As the demand for sustainable practices continues to grow, we must prioritize innovative solutions that ensure the longevity and health of our planet while still meeting the needs of various sectors.

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.