GUANFENG FOOD MACHINERY

main products include freeze-drying, drying, quick freezing, deep frying, pre-treatment, liquid nitrogen freezing, sterilization, cold chain storage and other food machinery equipment

Products Category

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

Integrated Vacuum Freeze Dryer

Product Category:

|

Integrated Vacuum Freeze Dryer Configuration |

|

|

Processing time |

10~20h |

|

Heating medium |

Water,oil ,silicone |

|

Heating method |

Electric/Steam |

|

Refrigerant |

R404A/R507 |

|

Vacuum time |

<15min |

|

Cold trap temperature |

-30℃~-45℃ |

|

Control method |

PLC |

|

Defrosting method |

water/Automatic alternating defrosting |

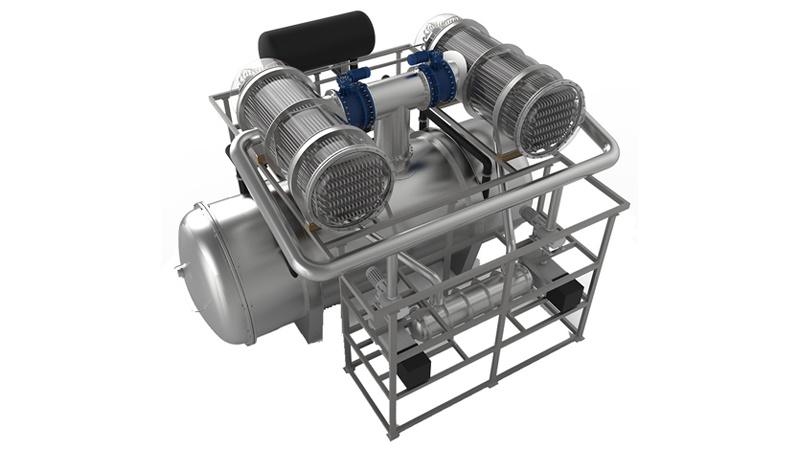

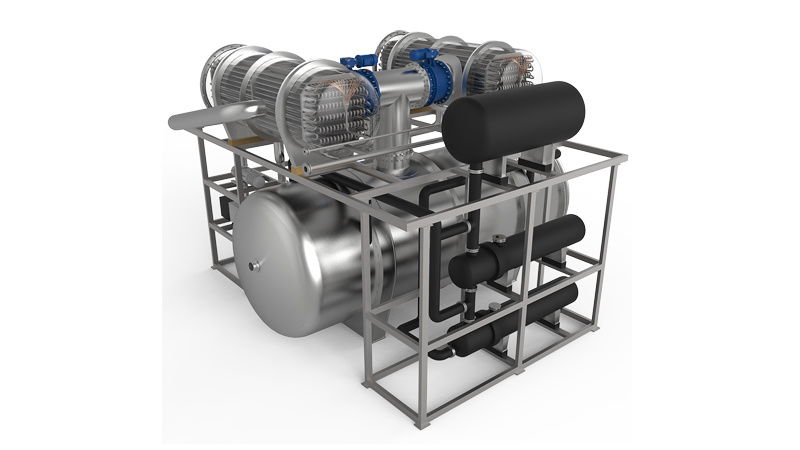

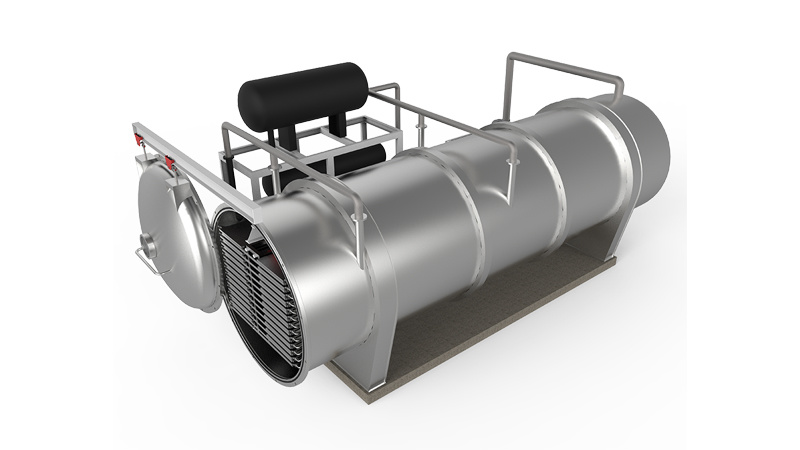

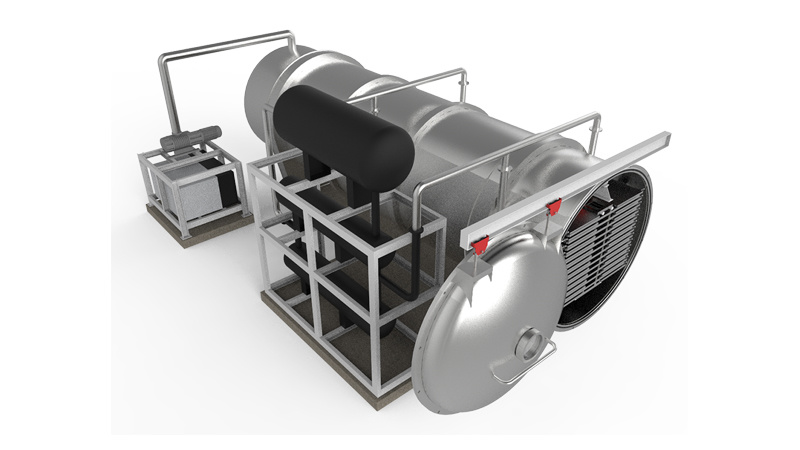

The Integrated Vacuum Freeze Dryer is a high-performance lyophilizer machine designed to preserve the original structure and biological activity of sensitive materials. By freezing the product at low temperatures and enabling moisture removal via sublimation under a controlled vacuum environment, this advanced vacuum freeze drying machine effectively maintains the chemical and physical properties of various substances. Its intelligent PLC-based control system ensures a seamless and automated process, reducing manual intervention while delivering consistent and repeatable results. Users benefit from a flexible heating system that supports multiple media including water, oil, and silicone, accommodating both electric and steam heating methods for broad applicability.

This quality vacuum freeze dryer is engineered for efficiency and reliability, with a rapid vacuum achievement time of under 15 minutes and a cold trap capable of reaching temperatures between -30°C to -45°C. The use of environmentally compliant refrigerants such as R404A/R507, combined with energy-efficient defrosting options like water or automatic alternating defrosting, ensures sustainable operation. With a typical processing cycle of 10 to 20 hours, this vacuum freeze dryer balances speed and quality, making it ideal for applications where precision and product integrity are critical. Its integrated design harmonizes the refrigeration, vacuum, heating, and control systems, offering a user-friendly experience with an emphasis on operational stability and ease of maintenance.

The Integrated Vacuum Freeze Dryer is a high-performance lyophilizer machine designed to preserve the original structure and biological activity of sensitive materials. By freezing the product at low temperatures and enabling moisture removal via sublimation under a controlled vacuum environment, this advanced vacuum freeze drying machine effectively maintains the chemical and physical properties of various substances. Its intelligent PLC-based control system ensures a seamless and automated process, reducing manual intervention while delivering consistent and repeatable results. Users benefit from a flexible heating system that supports multiple media including water, oil, and silicone, accommodating both electric and steam heating methods for broad applicability.

This quality vacuum freeze dryer is engineered for efficiency and reliability, with a rapid vacuum achievement time of under 15 minutes and a cold trap capable of reaching temperatures between -30°C to -45°C. The use of environmentally compliant refrigerants such as R404A/R507, combined with energy-efficient defrosting options like water or automatic alternating defrosting, ensures sustainable operation. With a typical processing cycle of 10 to 20 hours, this vacuum freeze dryer balances speed and quality, making it ideal for applications where precision and product integrity are critical. Its integrated design harmonizes the refrigeration, vacuum, heating, and control systems, offering a user-friendly experience with an emphasis on operational stability and ease of maintenance.

|

Integrated Vacuum Freeze Dryer Configuration |

|

|

Processing time |

10~20h |

|

Heating medium |

Water,oil ,silicone |

|

Heating method |

Electric/Steam |

|

Refrigerant |

R404A/R507 |

|

Vacuum time |

<15min |

|

Cold trap temperature |

-30℃~-45℃ |

|

Control method |

PLC |

|

Defrosting method |

water/Automatic alternating defrosting |

- Product Detail

- Product advantages

- 产品概要表格

-

- Commodity name: Integrated Vacuum Freeze Dryer

This all-in-one freeze dryer is designed to handle a wide range of food products, including fruits, vegetables, and meats. It’s equipped with multiple drying modes and adjustable settings, making it a versatile choice for businesses start-up and testing. Its robust design ensures long-lasting performance.

Integrated Vacuum Freeze Dryer Introduction:

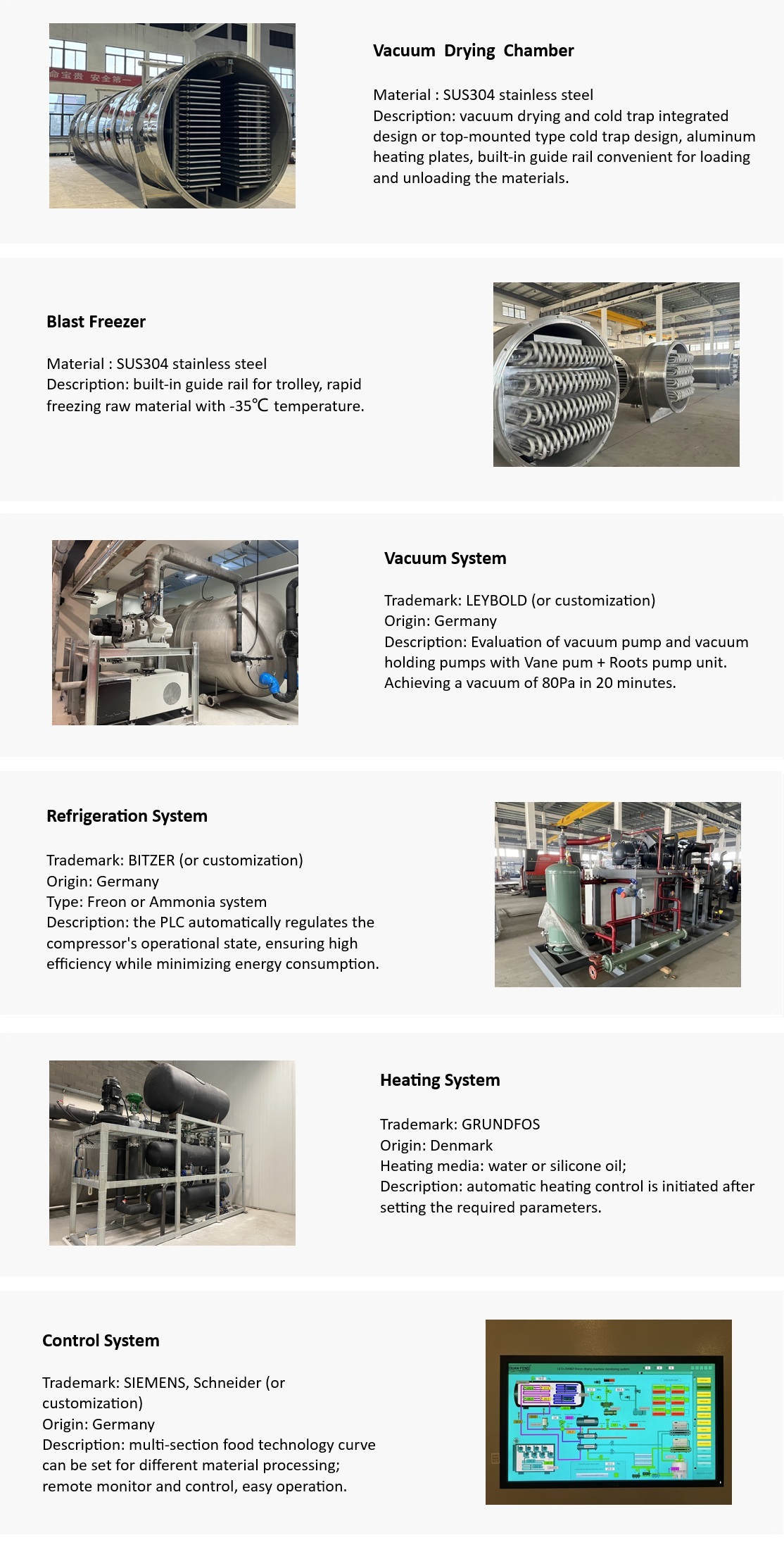

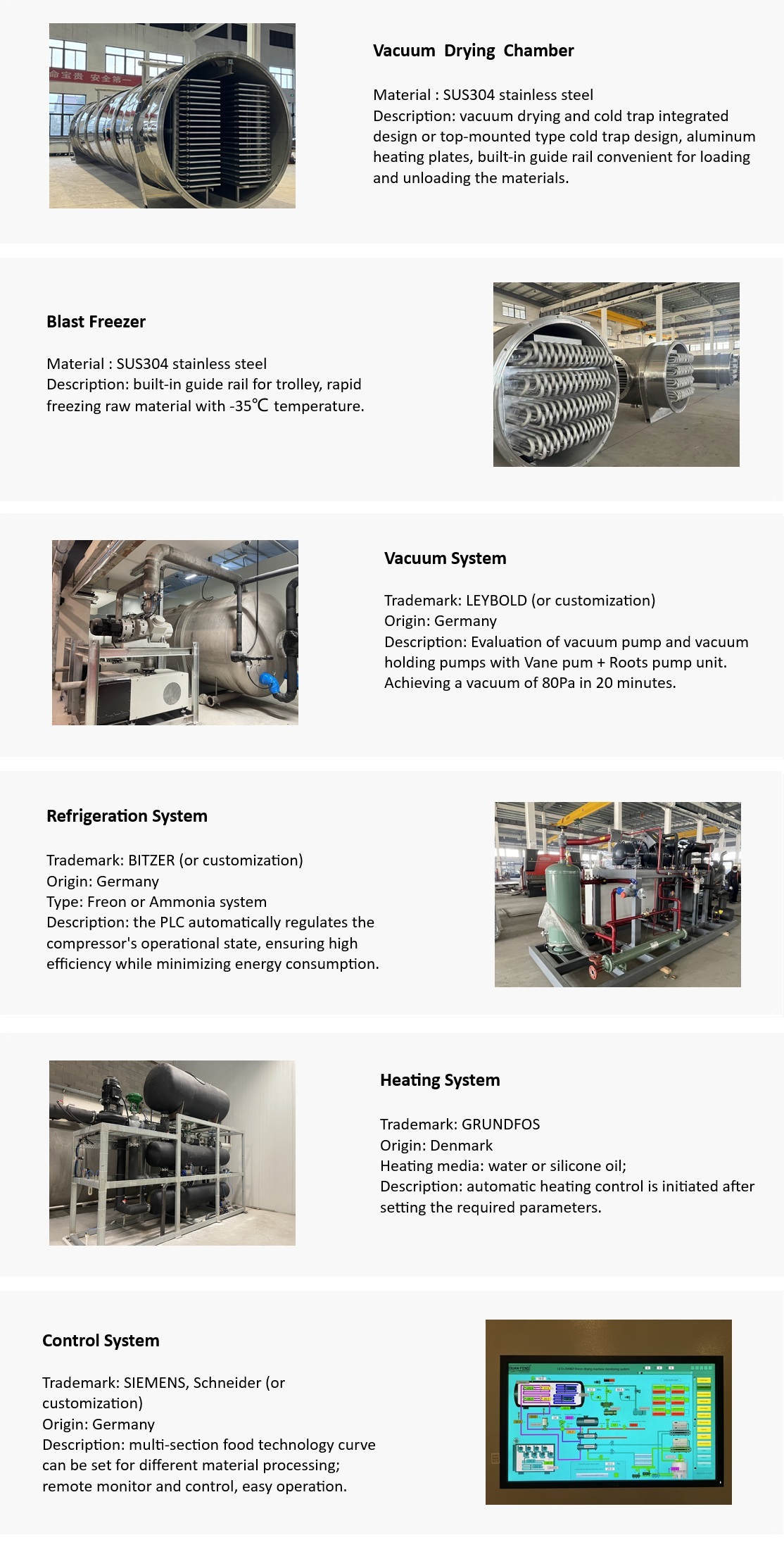

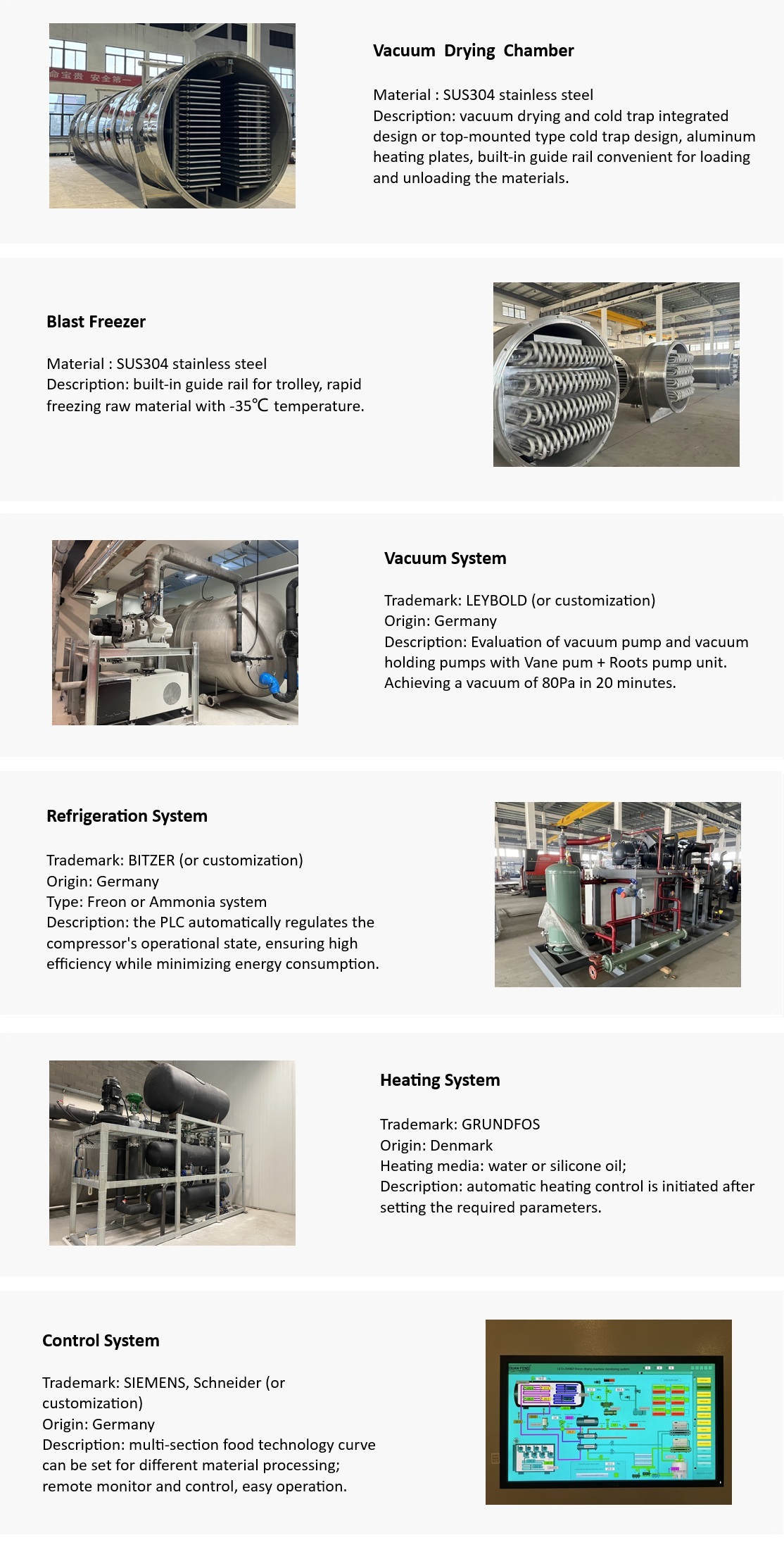

Integrated Vacuum Freeze Dryer the material at a low temperature and then removes moisture through sublimation under vacuum conditions. It is mainly composed of refrigeration system, vacuum system, heating system and control system. Each system works in coordination to dry materials efficiently and maintain their chemical and biological properties.

Integrated Vacuum Freeze Dryer Video:

Integrated Vacuum Freeze Dryer Parameter:

Model

GFD-5

GFD-10

GFD-25

GFD-50

GFD-100

GFD-125

GFD-150

GFD-200

Drying Area(㎡)

5

10

25

50

100

125

150

200

Average Dehydration(kg/h)

5

10

25

50

100

125

150

200

Number of Tray(pcs)

12

24

72

144

288

360

438

576

Size of Tray

780*540*30

540*645*30

Size of tank(m)

1.0*3.4

1.5*3.2

1.88*4.2

2.0*8.16

2.4*10.2

2.4*12

2.4*13.9

2.4*17.8

Operation Vacuum(Pa)

13.3~133Pa

Heating plate Temp.(℃)

Normal temperature ~ +120℃

Electric Heating(kw)

12

21

50

/

/

/

/

/

Steam Consumption(kg/h)

/

/

/

150

300

360

450

560

Cold Load Consumption(kw)

12

22

45

90

180

225

270

360

Installation Power(kw)

22

53

112

115

213

251

289

370

-

The Integrated Vacuum Freeze Dryer is a high-performance lyophilizer machine designed to preserve the original structure and biological activity of sensitive materials. By freezing the product at low temperatures and enabling moisture removal via sublimation under a controlled vacuum environment, this advanced vacuum freeze drying machine effectively maintains the chemical and physical properties of various substances. Its intelligent PLC-based control system ensures a seamless and automated process, reducing manual intervention while delivering consistent and repeatable results. Users benefit from a flexible heating system that supports multiple media including water, oil, and silicone, accommodating both electric and steam heating methods for broad applicability.

This quality vacuum freeze dryer is engineered for efficiency and reliability, with a rapid vacuum achievement time of under 15 minutes and a cold trap capable of reaching temperatures between -30°C to -45°C. The use of environmentally compliant refrigerants such as R404A/R507, combined with energy-efficient defrosting options like water or automatic alternating defrosting, ensures sustainable operation. With a typical processing cycle of 10 to 20 hours, this vacuum freeze dryer balances speed and quality, making it ideal for applications where precision and product integrity are critical. Its integrated design harmonizes the refrigeration, vacuum, heating, and control systems, offering a user-friendly experience with an emphasis on operational stability and ease of maintenance.

-

Integrated Vacuum Freeze Dryer Configuration

Processing time

10~20h

Heating medium

Water,oil ,silicone

Heating method

Electric/Steam

Refrigerant

R404A/R507

Vacuum time

<15min

Cold trap temperature

-30℃~-45℃

Control method

PLC

Defrosting method

water/Automatic alternating defrosting

GUANFENG FOOD MACHINERY

Product

Applications

Variety Fruits & Vegetables

GUANFENG freeze dryers can preserve the natural color, flavor, and nutritional value of various fruits and vegetables, making them convenient for long - term storage and rehydration.

Meat Products

To remove moisture from meat products, extending their shelf life while maintaining the texture and taste, suitable for a wide range of meat types

Seafood Products

By gently removing water through freeze - drying, our equipment helps retain the delicate flavor and texture of seafood, making it a great option for seafood processing.

Ready Meals

The freeze dryers are capable of preserving complete ready meals, ensuring that the flavors and ingredients remain intact, ready for quick reconstitution

Beverages Products

Our equipment can transform liquid beverages into convenient, powdered forms, retaining their taste and aroma for easy storage and transportation.

GUANFENG FOOD MACHINERY

Product

Recommendation

The capacity for this type is normally about 50kg-100kg per batch.

GUANFENG specializes in crafting customized solutions, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

GUANFENG specializes in crafting customized solutions, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

GUANFENG specializes in crafting customized solutions, facilitating adjustments in size, shape, and layout methodologies to maximize workflow efficiency and productivity.

Get

A Quote

Please leave your email address, our professionals will contact you as soon as possible!

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.