BLOG

Focus on hot topics, real-time dynamics

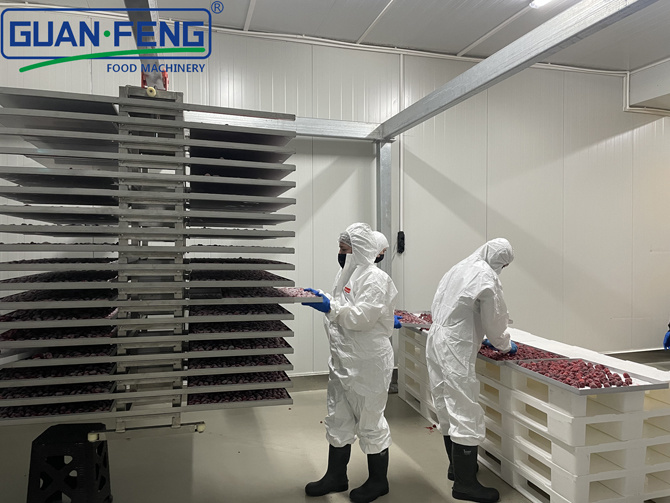

Vacuum Freeze Dryers: The Profit-Boosting Powerhouse for Food Businesses

Imagine slashing food waste by 90% while creating premium products customers crave. That’s the real-world magic a commercial Vacuum Freeze Dryer delivers for food producers, restaurants, and ingredient suppliers. Forget lab jargon – here’s how this tech transforms your bottom line:

Profit-Preserving Superpowers

⚡️ Lock in Value: Turn fragile berries, herbs, or surplus ingredients into shelf-stable gold (2-25 years!). No more dumping short-lived produce.

⚡️ Premium Pricing: Charge 3X more for vibrant freeze-dried mango slices vs. conventional dried goods.

⚡️ Reduce Logistics Costs: 70-90% lighter than fresh goods = cheaper shipping and storage.

A quality Vacuum Freeze Dryer isn’t an expense – it’s your new revenue stream.

Industry Game-Changers

✅ Ingredient Suppliers: Sell nutrition-packed powders (matcha, bone broth) to supplement brands.

✅ Ready-Meal Producers: Create lightweight camping/emergency meals with 5-year shelf life.

✅ Snack Innovators: Develop crunchy veggie chips or instant coffee crystals competitors can’t replicate.

✅ Restaurant Chains: Preserve seasonal ingredients year-round (think truffles or heirloom tomatoes).

Like an advanced sanitizing robot revolutionizes facility hygiene, freeze dryers upgrade your product portfolio from commodity to specialty.

Why Smart Businesses Choose Industrial Models

Modern Vacuum Freeze Dryer units (especially made in China with IEC/UL certifications) offer:

• PLC Automation: Set drying protocols for different products – no PhD required

• R507 Refrigerant: 30% faster processing than older models = more batches/month

• Steam/Electric Heating: Cut energy costs by matching your facility’s infrastructure

• Water Auto-Defrost: Zero downtime between cycles

Skip the cheap Vacuum Freeze Dryer traps – inconsistent results cost more in recalls and lost contracts. Invest in reliability.

Real ROI You Can Taste

🍓 Berry Farm Case: Freeze-dried "ugly fruit" outsold fresh at 200% margin

🍄 Mushroom Supplier: Exported powdered porcini to 15 countries (impossible fresh)

🍜 Meal Kit Startup: Reduced ingredient spoilage from 40% to 3%

The Future-Proof Move

With Chinese manufacturers offering modular systems (5kg to 500kg batches), scalable solutions exist for every business size. Pair this tech with your existing production line like you’d deploy an advanced sanitizing robot – seamlessly and profitably.

Bottom line: In an era of volatile supply chains and eco-conscious buyers, freeze drying isn’t just clever tech – it’s your insurance policy against waste and commodity competition. Let’s turn your perishables into profits!

Hot Tags:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.