BLOG

Focus on hot topics, real-time dynamics

Exploring the Benefits of a Vegetable Belt Dryer in Food Processing

Exploring the Benefits of a Vegetable Belt Dryer in Food Processing

Table of Contents

1. Introduction to Vegetable Belt Dryers

2. Understanding the Mechanism of Vegetable Belt Dryers

2.1. Key Components of Belt Dryers

2.2. How Heat and Airflow Work Together

3. Advantages of Using Vegetable Belt Dryers

3.1. Improved Quality of Dehydrated Vegetables

3.2. Enhanced Energy Efficiency in Food Processing

3.3. Increased Production Capacity

4. Comparing Vegetable Belt Dryers with Other Drying Methods

4.1. Belt Dryers vs. Freeze Dryers

4.2. Belt Dryers vs. Tray Dryers

5. Applications of Vegetable Belt Dryers in Food Processing

5.1. Common Vegetables Processed

5.2. Other Food Products Benefiting from Belt Drying

6. Maintenance Tips for Vegetable Belt Dryers

7. Regulatory Compliance and Safety Standards

8. Future Trends in Vegetable Dehydration Technology

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. Introduction to Vegetable Belt Dryers

In the food processing industry, the ability to effectively dehydrate vegetables plays a crucial role in preserving quality, enhancing flavors, and extending shelf life. Vegetable belt dryers have emerged as a preferred technology for achieving optimal drying results. This article aims to explore the myriad benefits of utilizing a vegetable belt dryer in food processing, showcasing how this efficient system can elevate the overall quality of dehydrated products.

2. Understanding the Mechanism of Vegetable Belt Dryers

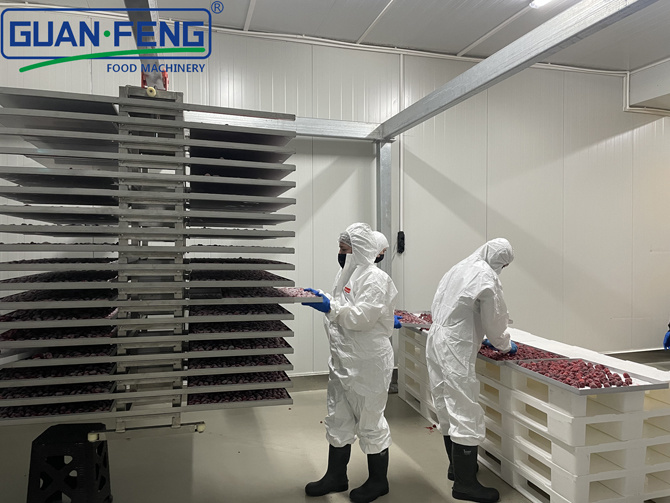

The vegetable belt dryer operates on a continuous drying principle, utilizing a conveyor belt system to facilitate the drying process. By passing vegetables through a controlled heating and airflow environment, the moisture content is effectively reduced without compromising quality.

2.1. Key Components of Belt Dryers

A vegetable belt dryer comprises several key components, including:

- **Conveyor Belt:** This is the main component that transports the vegetables through the drying chamber. The material of the belt is designed to withstand high temperatures and ensure even drying.

- **Heating System:** The heating system generates the necessary temperature for moisture evaporation. It can be powered by electric, gas, or hot air sources.

- **Airflow System:** Proper airflow is essential to remove moisture-laden air from the drying chamber and replace it with fresh, heated air.

2.2. How Heat and Airflow Work Together

Effective drying requires the right balance of heat and airflow. The heat increases the temperature of the vegetables, encouraging the moisture to evaporate. Simultaneously, the airflow carries the moist air away from the drying chamber, allowing for continuous drying without reintroducing moisture.

3. Advantages of Using Vegetable Belt Dryers

The adoption of vegetable belt dryers in food processing brings numerous advantages that enhance overall productivity and product quality.

3.1. Improved Quality of Dehydrated Vegetables

One of the most significant benefits of vegetable belt dryers is their ability to produce high-quality dehydrated vegetables. The controlled drying conditions minimize nutrient loss and preserve the natural color, flavor, and texture. As a result, consumers can enjoy products that retain their original characteristics.

3.2. Enhanced Energy Efficiency in Food Processing

Energy consumption is a critical factor in food processing operations. Vegetable belt dryers are designed with energy efficiency in mind. By optimizing heating methods and airflow management, these dryers significantly reduce energy costs compared to traditional drying methods.

3.3. Increased Production Capacity

The continuous operation of belt dryers allows food processing facilities to achieve higher production rates. Unlike batch drying systems, vegetable belt dryers can process large quantities of vegetables simultaneously, making them ideal for industrial applications.

4. Comparing Vegetable Belt Dryers with Other Drying Methods

Understanding the advantages of vegetable belt dryers becomes clearer when comparing them to other drying methods commonly used in the food industry.

4.1. Belt Dryers vs. Freeze Dryers

Freeze drying is often regarded as a premium method for preserving food quality. However, it comes with high operational costs and longer processing times. In contrast, vegetable belt dryers offer a more cost-effective and faster alternative without significantly compromising quality.

4.2. Belt Dryers vs. Tray Dryers

Tray dryers require manual loading and unloading of trays, which can be labor-intensive and time-consuming. Belt dryers streamline the process, allowing for continuous movement and automated operations, thus enhancing efficiency.

5. Applications of Vegetable Belt Dryers in Food Processing

Vegetable belt dryers are versatile and can be utilized in various applications within the food processing sector.

5.1. Common Vegetables Processed

A wide range of vegetables can be efficiently dehydrated using belt dryers, including:

- **Carrots**

- **Bell Peppers**

- **Tomatoes**

- **Onions**

- **Potatoes**

5.2. Other Food Products Benefiting from Belt Drying

In addition to vegetables, belt dryers can also be applied to process fruits, herbs, and even certain types of grains, showcasing their flexibility in the food industry.

6. Maintenance Tips for Vegetable Belt Dryers

To keep vegetable belt dryers operating at peak performance, regular maintenance is essential. Here are some tips:

- **Routine Cleaning:** Ensure that the belt and drying chamber are cleaned regularly to prevent residue buildup.

- **Inspect Components:** Regularly check the heating elements, airflow systems, and conveyor belts for wear and tear.

- **Calibration Checks:** Periodically calibrate temperature and airflow settings to maintain optimal drying conditions.

7. Regulatory Compliance and Safety Standards

Compliance with safety and regulatory standards is paramount in food processing. Vegetable belt dryers must adhere to guidelines set by organizations such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). Ensuring proper certification not only guarantees product safety but also enhances marketability.

8. Future Trends in Vegetable Dehydration Technology

As technology continues to evolve, several trends are emerging in the realm of vegetable dehydration:

- **Smart Technology Integration:** Incorporating IoT (Internet of Things) technology allows for real-time monitoring and data analysis, improving efficiency and reducing waste.

- **Sustainability Practices:** With an increasing focus on environmental responsibility, manufacturers are exploring eco-friendly materials and energy sources to power drying equipment.

9. Frequently Asked Questions (FAQs)

**Q1: What types of vegetables are best suited for belt drying?**

A1: Vegetables such as carrots, bell peppers, tomatoes, and onions are particularly well-suited for belt drying due to their moisture content and structural properties.

**Q2: How does a vegetable belt dryer compare in cost to other drying methods?**

A2: Vegetable belt dryers typically offer a more cost-effective solution compared to both freeze dryers and tray dryers, thanks to their continuous operation and energy efficiency.

**Q3: Can belt dryers handle large-scale production?**

A3: Yes, vegetable belt dryers are designed for industrial applications and can handle large volumes of product efficiently.

**Q4: What maintenance is required for a vegetable belt dryer?**

A4: Regular cleaning, inspection of components, and calibration checks are essential for maintaining optimal performance.

**Q5: Are vegetable belt dryers energy-efficient?**

A5: Yes, they are designed to maximize energy efficiency, reducing operational costs and environmental impact.

10. Conclusion

In summary, the vegetable belt dryer represents a cutting-edge solution in food processing, offering numerous benefits that enhance product quality, increase energy efficiency, and streamline production processes. By adopting this technology, food processors can meet consumer demands for high-quality dehydrated vegetables while maintaining compliance with industry regulations. The future of vegetable dehydration looks promising, with continuous advancements paving the way for even greater efficiency and sustainability in the food industry. Embracing vegetable belt dryers not only prepares your business for the demands of the modern market but also contributes positively to the environment and overall food quality.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.