BLOG

Focus on hot topics, real-time dynamics

Maximizing Efficiency with Yam Belt Dryers in Industrial Operations

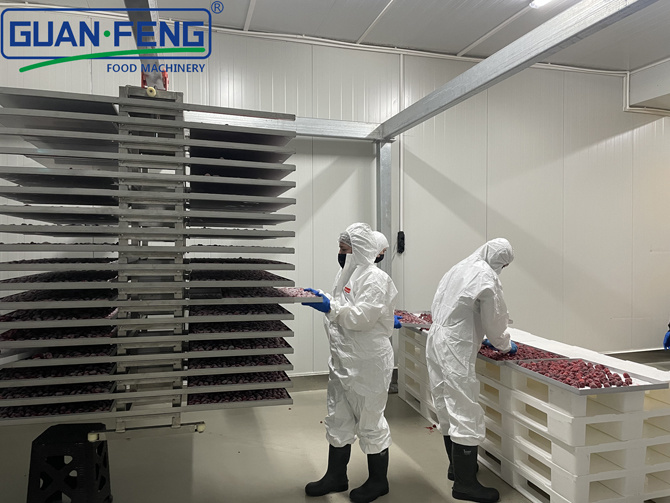

Yam belt dryers are an essential component in the industrial drying equipment landscape, particularly for industries that require efficient and effective drying solutions. These systems utilize a continuous conveyor belt to transport materials through a heated chamber, where moisture is evaporated. This method of drying is particularly advantageous for agricultural products like yams, as it ensures uniform drying while preserving the quality of the product.

One of the primary benefits of using a yam belt dryer is its efficiency. The continuous operation allows for large volumes of product to be dried in a relatively short period. Traditional drying methods, such as sun-drying or batch drying, can be time-consuming and heavily dependent on environmental conditions. In contrast, yam belt dryers operate independently of weather factors, providing a reliable solution for year-round production.

Moreover, these dryers are designed with energy efficiency in mind. Many models incorporate advanced technologies that optimize airflow and heating methods, reducing energy consumption and operational costs. This is particularly important for businesses looking to minimize their environmental footprint while maintaining profitability. By investing in a yam belt dryer, companies can achieve a more sustainable operation, aligning with the growing demand for environmentally friendly practices in the industry.

When considering the implementation of a yam belt dryer, it's crucial to evaluate the specific needs of your operation. Factors such as the type of material being dried, required output capacity, and space availability should be taken into account. Additionally, understanding the maintenance requirements and potential operational challenges can aid in the selection of the right system for your needs.

Another important aspect is the integration of control systems. Modern yam belt dryers often come equipped with sensors and automated controls that monitor moisture levels and adjust drying parameters accordingly. This not only enhances product quality but also reduces the risk of over-drying or under-drying, which can compromise the final product's integrity.

In conclusion, yam belt dryers present an ideal solution for industries requiring efficient and consistent drying methods. Their ability to operate independently of environmental conditions, combined with energy efficiency and advanced control features, makes them a valuable asset for any industrial operation focused on improving productivity and quality. When selecting a yam belt dryer, ensure to assess your specific needs and operational goals to make an informed decision that will benefit your business in the long run.

One of the primary benefits of using a yam belt dryer is its efficiency. The continuous operation allows for large volumes of product to be dried in a relatively short period. Traditional drying methods, such as sun-drying or batch drying, can be time-consuming and heavily dependent on environmental conditions. In contrast, yam belt dryers operate independently of weather factors, providing a reliable solution for year-round production.

Moreover, these dryers are designed with energy efficiency in mind. Many models incorporate advanced technologies that optimize airflow and heating methods, reducing energy consumption and operational costs. This is particularly important for businesses looking to minimize their environmental footprint while maintaining profitability. By investing in a yam belt dryer, companies can achieve a more sustainable operation, aligning with the growing demand for environmentally friendly practices in the industry.

When considering the implementation of a yam belt dryer, it's crucial to evaluate the specific needs of your operation. Factors such as the type of material being dried, required output capacity, and space availability should be taken into account. Additionally, understanding the maintenance requirements and potential operational challenges can aid in the selection of the right system for your needs.

Another important aspect is the integration of control systems. Modern yam belt dryers often come equipped with sensors and automated controls that monitor moisture levels and adjust drying parameters accordingly. This not only enhances product quality but also reduces the risk of over-drying or under-drying, which can compromise the final product's integrity.

In conclusion, yam belt dryers present an ideal solution for industries requiring efficient and consistent drying methods. Their ability to operate independently of environmental conditions, combined with energy efficiency and advanced control features, makes them a valuable asset for any industrial operation focused on improving productivity and quality. When selecting a yam belt dryer, ensure to assess your specific needs and operational goals to make an informed decision that will benefit your business in the long run.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:

sales@syguanfeng.com

Tel:

+86 15088506234

Address:

South Industrial Park of Dongguan, Shangyu District, Shaoxing City,Zhejiang Province,China.

GUANFENG, your customization experts!

GUANFENG FOOD MACHINERY - leading supplier of integrated food processing solutions

Copyright© 2024 ZHEJIANG GUANFENG FOOD MACHINERY CO.,LTD.